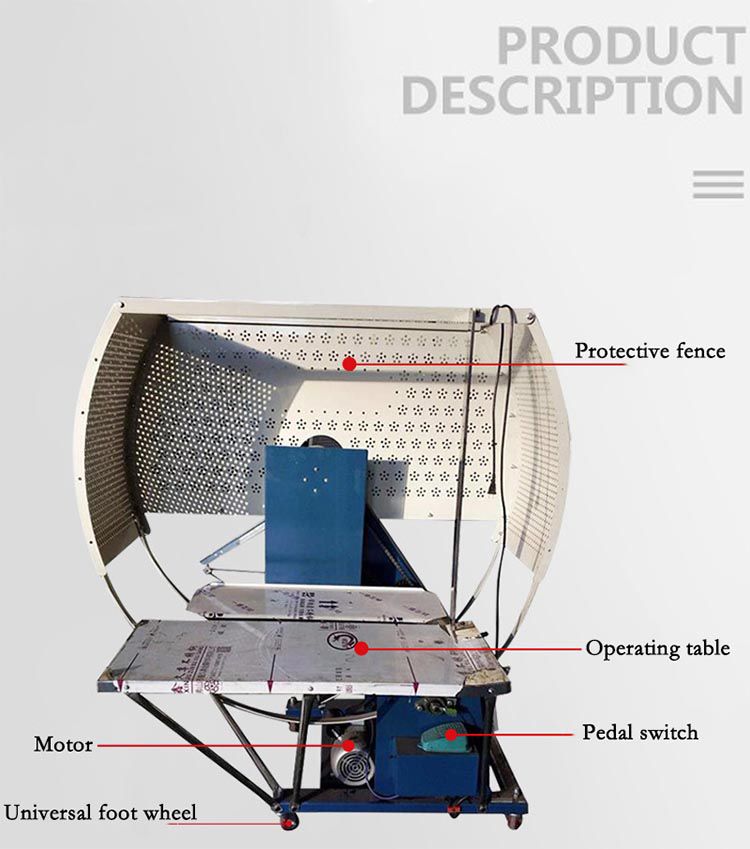

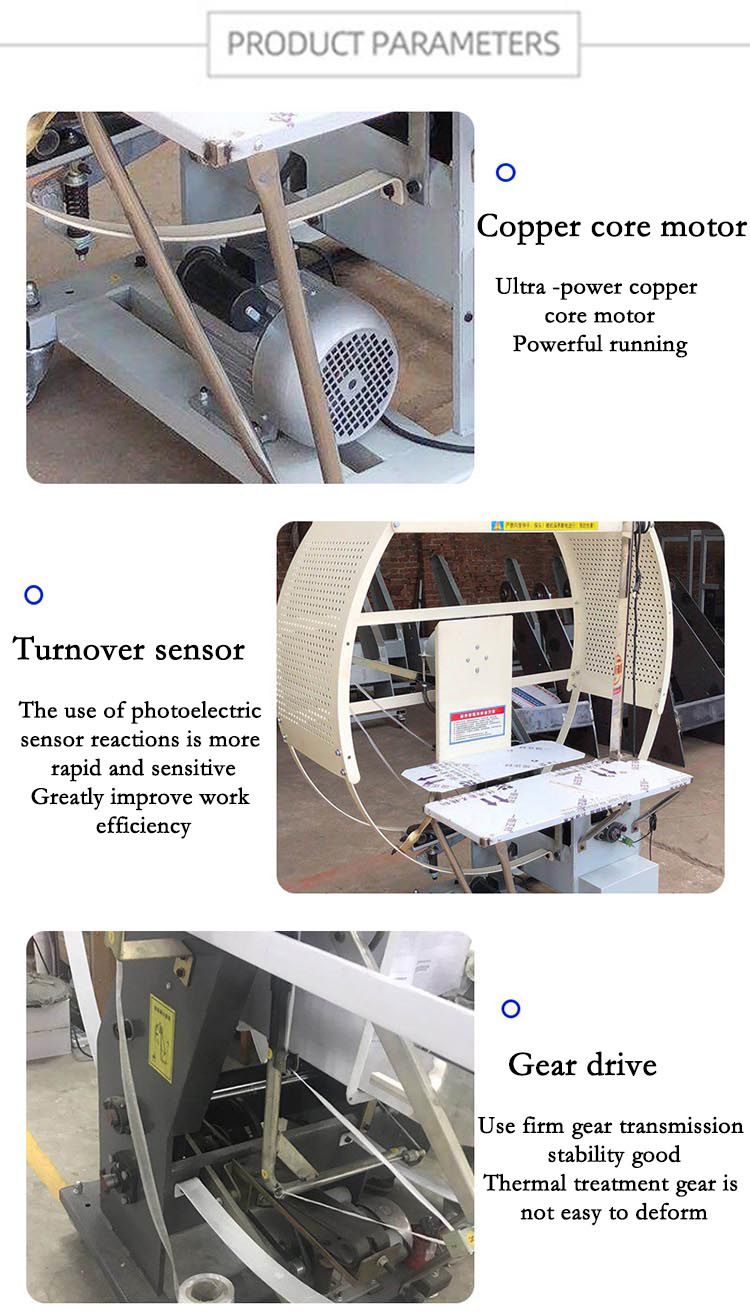

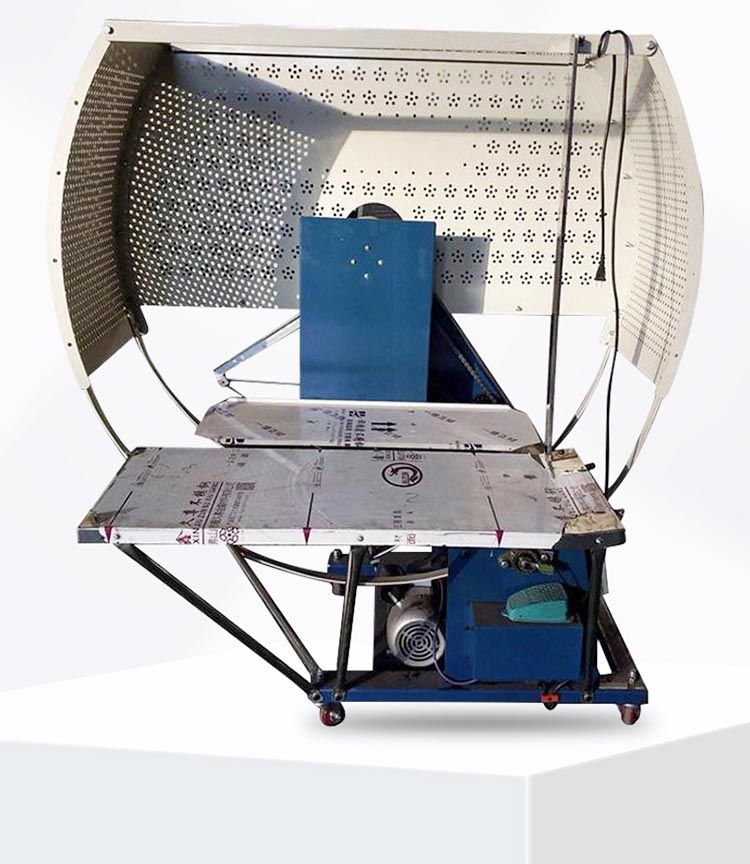

Bundle Tying Machine Pallet Plastic Carton Box Packing Strapping Machine

Bundle Tying Machine Pallet Plastic Carton Box Packing Strapping Machine

Bundle Tying Machine (additionally called an automatic baler) is a mechanical device used to instantly strap and bundle items such as cartons, textiles, plastic bags, and ended up bundles. It safely affixes the strapping tape to the item or bundle via automated feeding, tensioning, heat-melt sealing, and reducing operations, facilitating handling, storage, and transportation.

| Product Paramenters | |

Max packing size | 450×450mm |

| Min packing size | 30×90mm |

| Baffle depth | 230 |

| Power | 1/4HP |

| Length | 980mm |

| Width | 780mm |

| Height | 1500mm |

| Weight | 165KG |

I. Working Concept of an Bundle Tying Machine:

Automatic strapping makers commonly complete the strapping procedure with the adhering to steps:

Automatic Strapping: The equipment immediately supplies the strapping tape to the working setting according to the settings.

Induction Begin: When a thing is placed in the strapping area, the equipment automatically detects the area and begins the strapping procedure.

Strap Tightening up: The strapping tape is automatically tightened to a predetermined tension to ensure a safe and secure strap.

Hot Melt Bonding/Heat Sealing: The strapping tape is linked at both ends via high-temperature fusion, removing the demand for metal fastenings.

Cutting: Excess tape is instantly removed after bonding. The whole process takes only 1-3 secs.

II. Category of Bundle Tying Machine:

| Classification | Type | Description |

| Depending on the operating method | Fully automatic strapping machines | require no manual operation and automatically feed, wrap, and cut straps |

| Semi-automatic strapping machines | require manual strap insertion or trigger activation | |

| By structure type | Tabletop strapping machines | Small desktop models suitable for light packaging |

| Floor-standing (vertical) strapping machines | Suitable for large packages and suitable for industrial use | |

| Depending on the strapping direction | Horizontal / vertical strapping machines | Suitable for packaging goods of different volumes and stacking methods |

III. Scope of Application:

Automatic strapping devices are widely made use of in the adhering to markets:

Fiber processing plants: Packaging completed products such as cushion cores, dolls, and quilts

Home textile plants: Compressing and packaging materials, duvet cores, and bedding

Electronics market: Loading boxed electrical devices

Logistics and warehousing: Packing and strapping containers

Food product packaging plants: Packing drink cartons and cartons

Publishing plants/bookbinding plants: Packaging completed publications and cartons

IV. Advantages of Bundle Tying Machine:

Raised strapping efficiency, with a solitary equipment capable of hundreds of times per hour

Constant and cool packaging, enhancing product image

Lowered labor strength, with a single person able to operate numerous makers

Flexible strapping stress to fit different products and weights

Reliable strapping, minimizing waste and expenses

V. Suitable Customers:

Production and processing business with large daily shipments

Factories seeking improved packaging performance and looks

Customers seeking to lower manual strapping and execute computerized production lines