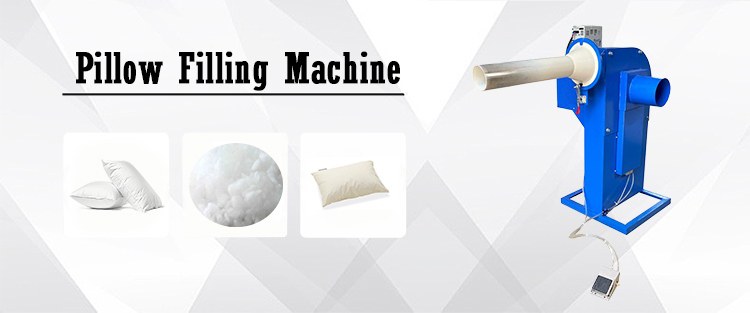

Cotton Stuffing Filling Machine Stable Performance Upholstery Fiber Filling Machine Cotton Charging Machine

Cotton Stuffing Filling Machine Stable Performance Upholstery Fiber Filling Machine Cotton Charging Machine

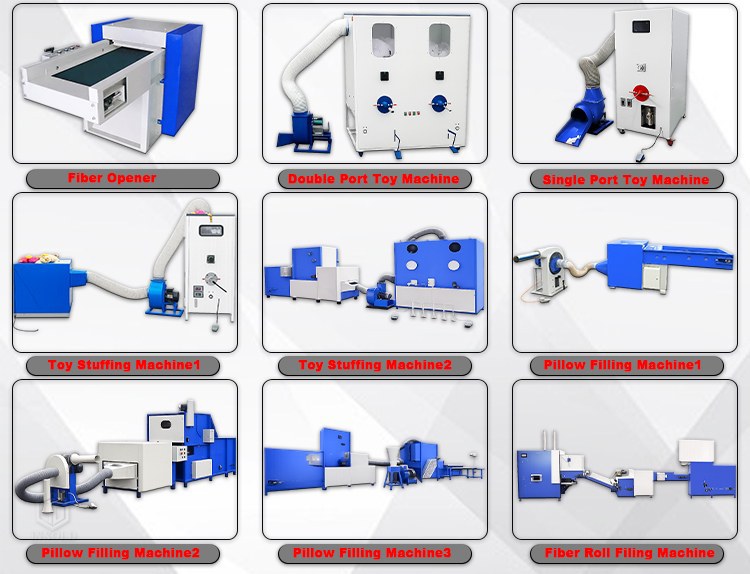

Cotton Charging Machine is a specialized piece of equipment used to evenly and quickly fill products with opened and loosened fiber materials such as chemical fiber cotton, PP cotton, hollow fiber cotton, and recycled cotton, using high-speed airflow or mechanical conveying methods.

| Model | AB-320-1 | AB-420-1 |

| Size | 650*1000*850mm | 650*1000*850 |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 110kg | 120kg |

This Upholstery Fiber Filling Machine is widely used in:

Pillow filling

Cushion filling

Doll filling

Seat cushion/backrest filling

Sofa backrest filling

Home textile product filling

It is one of the core production equipment in modern home textile, toy, and upholstered furniture factories.

Working Principle of Automatic Pillow Making Machine:

The fiber filling machine is usually used in conjunction with a fiber Opening Machine. The overall workflow is as follows:

1. Raw materials (PP cotton / chemical fiber cotton) are opened.

2. The loose fibers enter the filling machine's cotton storage bin.

3. A stable airflow is generated by a high-speed fan.

4. The fibers are evenly transported to the filling pipe.

5. The operator inserts the filling nozzle into the product.

6. The fibers are quickly and fluffily filled into the product.

The filling process is fast, uniform, does not clump, and does not damage the fiber structure.

Main Structural Components of Sofa Filling Equipment:

1. Main frame: Thickened steel plate structure, high stability, suitable for long-term continuous operation.

2. High-pressure fan system: Strong suction and large airflow ensure rapid fiber transport and high filling efficiency.

3. Filling pipe: Perforated stainless steel or carbon steel pipe with anti-clogging design for uniform filling.

4. Electrical control system: Independent control box, one-button start/stop, safe and reliable.

5. Foot switch: Frees up hands, improves filling accuracy, and makes operation safer.

Main Advantages of Filler For Stuffed Animals:

1. Fast filling speed: 5-10 times more efficient than manual filling, suitable for mass production.

2. Uniform and fluffy filling: Fibers do not knot, and the finished product has good resilience.

The appearance is full and natural.

3. Simple operation: One person can operate it; new employees can learn in 10 minutes.

4. Wide range of applicable materials: PP cotton, hollow siliconized cotton, ordinary chemical fiber cotton, recycled cotton, down alternative cotton, doll-specific filling cotton.

5. Saves labor costs: Can replace 3-5 workers; the return on investment is very fast with long-term use.