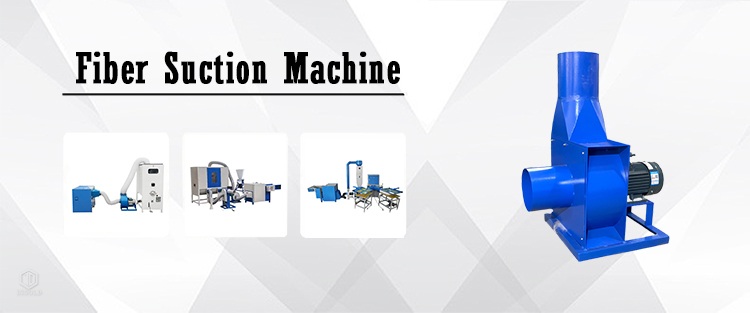

Cotton Suction Machine Industrial For Fiber Opener Toy Stuffing Machine

Cotton Suction Machine Industrial For Fiber Opener Toy Stuffing Machine

The Cotton Suction Machine is a special conveying equipment that uses the airflow negative pressure principle to "suck" loose fiber cotton (such as polyester fiber cotton, down, PP cotton, pearl cotton, etc.) from the silo or bag and transport it to the next process (such as opener, Quantitative Filling Machine, filling machine). It is widely used in modern home textiles, toys, clothing and recycled fiber recycling production lines, which can effectively replace manual handling and improve the level of production automation.

| Model | AB420-6 | AB430-6 |

| Size | 450*650*600mm | 450*650*600mm |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 140kg | 140kg |

Main functions and advantages Cotton Suction Machine:

Automatic conveying: Realize long-distance and arbitrary angle conveying of raw materials, reduce the labor intensity of manual handling.

Uniform feeding: The airflow entrainment method avoids fiber agglomeration and partial aggregation, ensures uniform feeding of the next equipment, and improves the opening and metering accuracy.

Environmental protection and cleanliness: closed pipelines and high-efficiency filtration suppress fiber scraps and dust flying, and improve the workshop environment.

Flexible layout: The pipeline layout is simple, and the suction point can be quickly adjusted according to the production line station, supporting multi-point centralized or dispersed feeding.

Space saving: Compared with spiral conveying or vibration feeding, the cotton suction machine pipeline occupies less space and is more suitable for intensive production workshops.

Application scenarios Cotton Suction Machine:

Opener feeding: The cotton wool in the storage bin or large bag is directly conveyed to the feed port of the opener to achieve continuous production.

Quantitative Cotton Filling Machine front end: Provide stable and uniform raw material input for the quantitative cotton filling machine, improve metering accuracy and production efficiency.

Fiber regeneration processing: In the fiber recycling and regeneration production line, the recycled cotton after crushing or opening is uniformly sucked into the separation, screening or mixing equipment.

Multi-machine linkage center feeding: One cotton suction machine can serve multiple downstream equipment, and distribute fiber cotton on demand through branch pipelines and solenoid valves