Drum Sanding Machine High Precision Wood Wood Planer Polishing Sander For Panels For Sale

Drum Sanding Machine High Precision Wood Wood Planer Polishing Sander For Panels For Sale

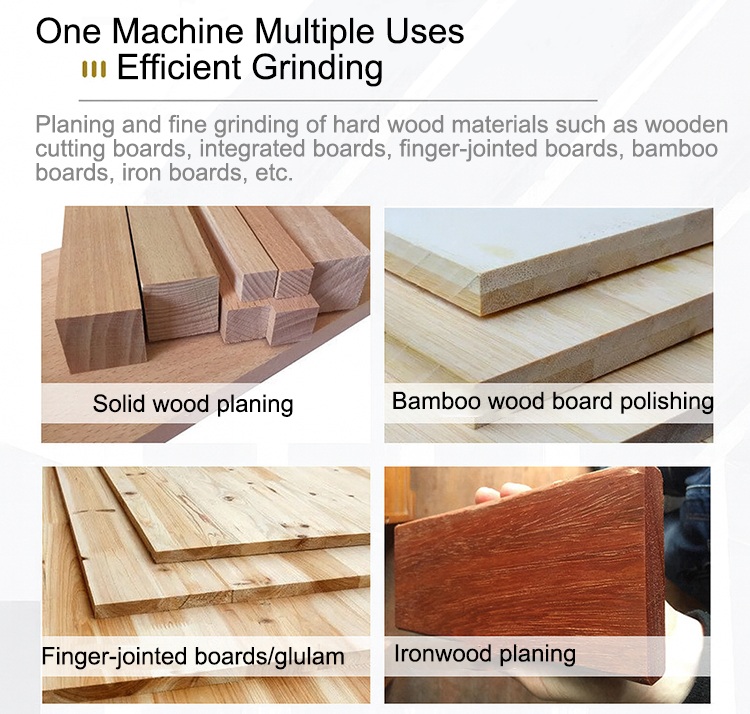

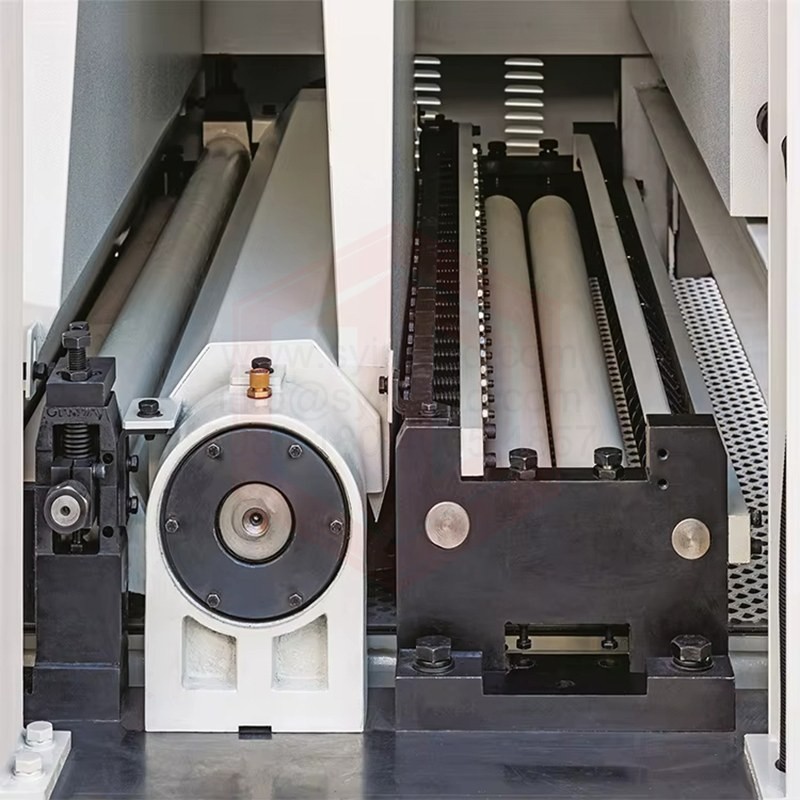

Drum Sanding Machine is a mechanical device that planes and smoothes wood surfaces. It's a key piece of equipment used in industries like wood processing, furniture manufacturing, and flooring production. It's like a combination of a planer and a sander, capable of achieving thickness, smoothing, and finishing in a single operation.

| Specifications | D-RP630 | D-RP1000 | D-RP1300 |

| Working Width | 630mm | 1000mm | 1300mm |

| Working Thickness | 2-200mm | 2-200mm | 2-120mm |

| 1# Sanding Belt Speed | 18m/min | 18m/min | 18m/min |

| 2# Sanding Belt Speed | 14m/min | 12m/min | 12m/min |

| Conveyor Belt Height | 5-25m/s | 5-25m/s | 5-25m/s |

| Sanding Belt Dimensions | 650*1920mm | 1020*2020mm | 1320*2020mm |

| Total Motor Power | 20.37-35.37kw | 20.77-38.87kw | 56.55-75.55kw |

| Stroke Height | 120-200mm | 120-200mm | 120-200mm |

| Operating Air Pressure | 0.5Mpa | 0.6Mpa | 0.6Mpa |

| Suction Air Speed | 25m/s | 25m/s | 25m/s |

| Suction Air Volume | 5000m³/h | 5000m³/h | 5000m³/h |

| Dimensions | 1700*1100*2050mm | 1700*1400*2050mm | 2700*2200*2050mm |

| Net Weight | 1000kg | 2000kg | 3000kg |

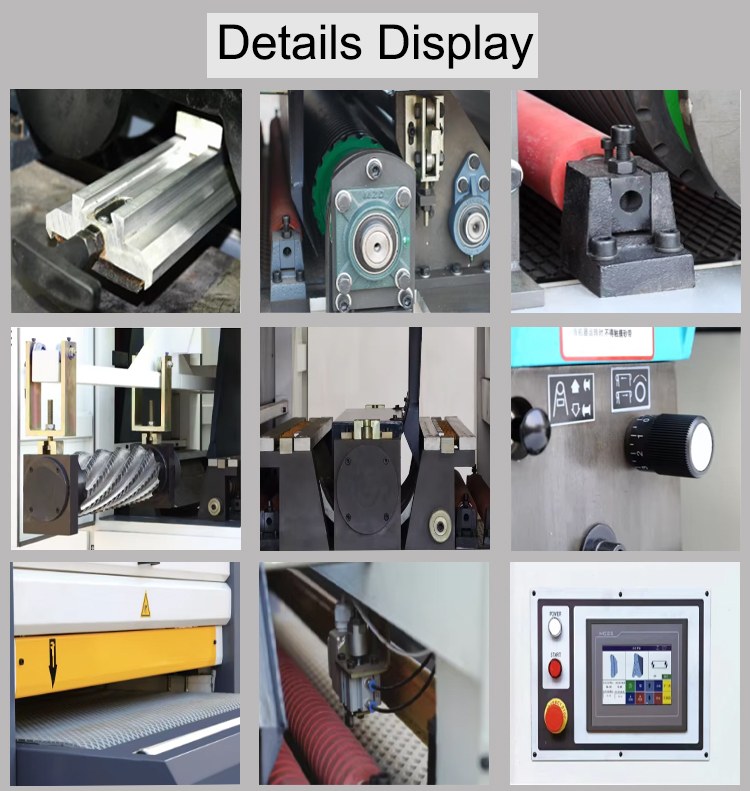

Features of Drum Sanding Machine:

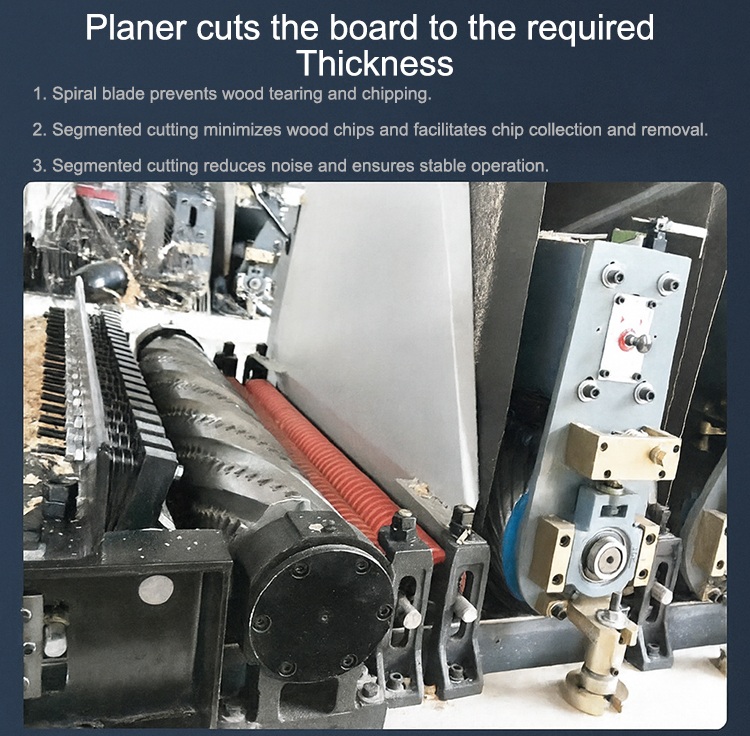

1. The planer is a sanding machine specifically designed for solid wood paneling. The planer shaft utilizes a 15mm x 15mm German-made Tiger Head blade, which is the most commonly used internationally. It features high-efficiency and wear-resistant blades. The conveyor utilizes a frequency converter, ensuring global service and stability. This is a strong, anti-interference feature.

3. The support utilizes a cast iron structure for stable pressure and deformation, ensuring precise sanding and a perfect sanding effect.

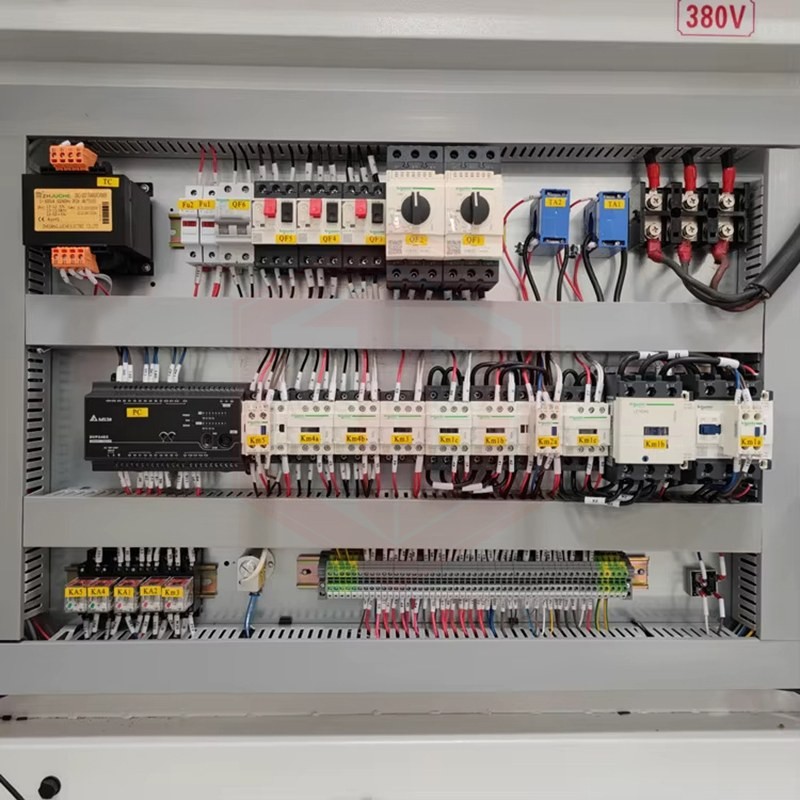

4. The main electrical components are genuine Chint brand components, ensuring stable operation.

5. The machine utilizes imported planer rollers, calibrating rollers, and soft rubber rollers (or a combination sanding frame). The planing, sanding, and polishing process is highly efficient and energy-efficient.

6. A casting backstop prevents the board from rebounding and injuring personnel during processing.