Fiber Mix Machine High Power Popular For Toy Pillow Cotton Stuffing Machines

Fiber Mix Machine High Power Popular For Toy Pillow Cotton Stuffing Machines

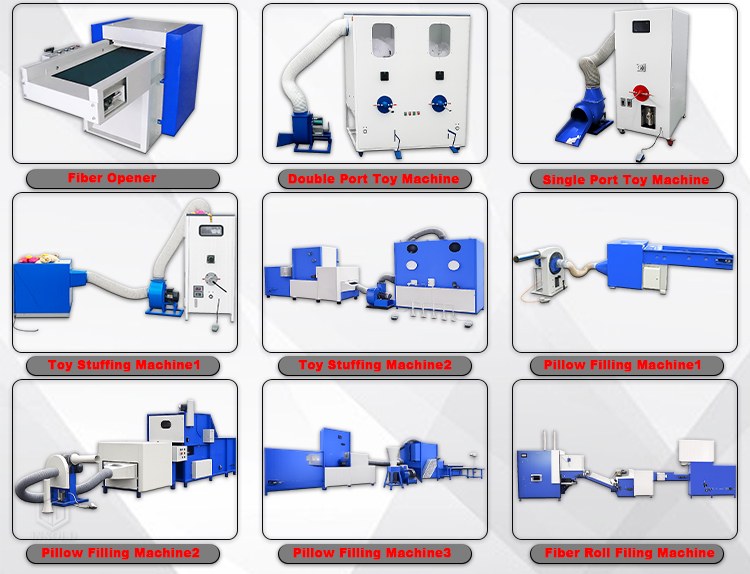

The Fiber Mix Machine is used in sofa factory, pillow factory and toy factory. It aims to mix all kinds of loosen short fiber or doll cotton with other filling materials (such as: broken sponge, wool, feather and so on)evenly.

It connects with the doll Cotton Filling Machine and can fill it in the designated cloth bag. Our company can provide the corresponding machinery and equipment according to the actual cotton scale requirements of customers.

| Model | AB1000-2 | AB1250-2 |

| Size | 1000*1300*1700mm | 1250*1550*1700mm |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 160kg | 180kg |

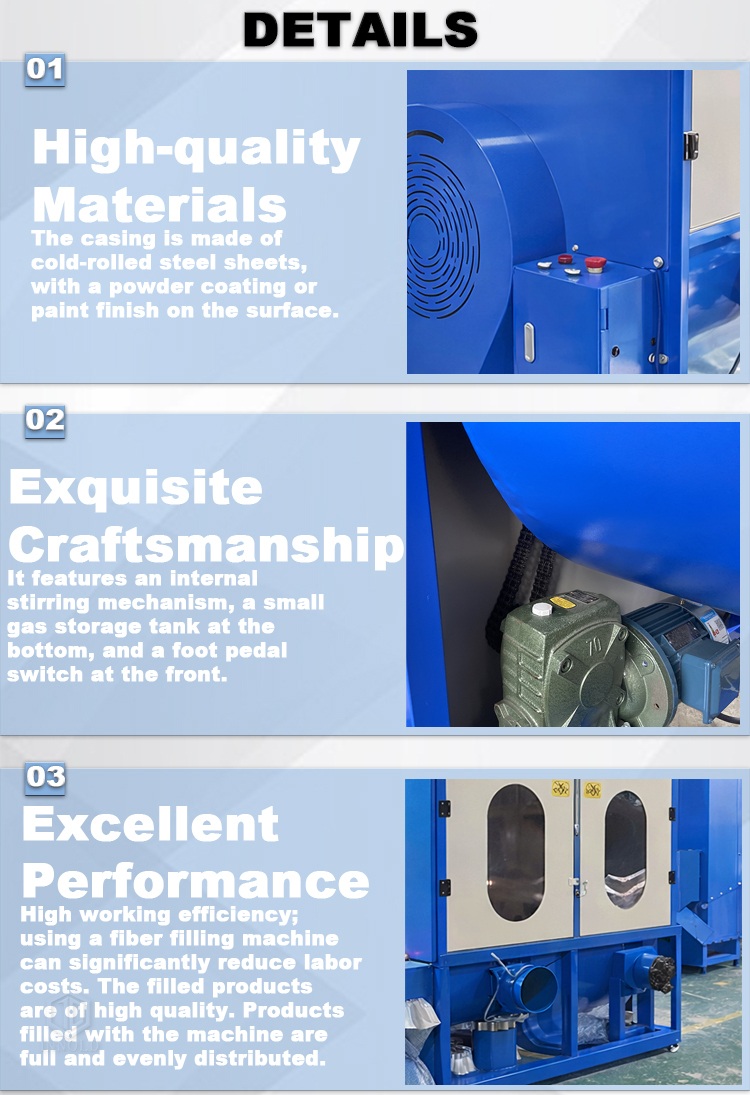

Structure and composition Fiber Mix Machine:

Box

Mostly made of welded steel plates or aluminum alloy profiles, the inner wall is smooth and anti-sticky, and the bottom is slightly tilted to help the fiber slide down.

Partition/partition

2-4 compartments can be set inside, and raw materials from different warehouse numbers or different suppliers can be loaded separately through manual or pneumatic gates.

Mixing device

The top or side is equipped with a vibration motor, a screw propeller or a pneumatic purge pipe to gently flip and stir the fibers in the box.

Discharge port

The bottom is equipped with an adjustable gate, which cooperates with the feeding screw or the discharge port to achieve quantitative or continuous feeding.

Control system (optional)

The simple model controls the vibration and gate by manual switch; the high-end model is equipped with PLC, which can set the mixing time, gate opening and discharge rhythm.

Main functions and advantages Fiber Mix Machine:

Batch uniformity: effectively eliminate the batch differences between the same batch of raw materials and ensure the consistency of feeding of downstream equipment.

Improve quality: the mixed fibers are more balanced in color difference, fineness, length, etc., and the final fabric or non-woven fabric is smoother and more stable.

Save labor: automatic or semi-automatic mixing process, reducing manual layering and sorting work.

Strong compatibility: can process natural and synthetic fibers such as cotton, polyester, viscose, wool, and recycled fiber materials.