Hf Hot Press Machine Veneer Insulating Heating Plates Laminating Furniture Panel Hot Press Machine

Hf Hot Press Machine Veneer Insulating Heating Plates Laminating Furniture Panel Hot Press Machine

Hf Hot Press Machine uses a hydraulic system to generate strong pressure, while a heating plate (hot press plate) provides a stable high temperature. This rapidly cures the glue in the wood or artificial board, firmly bonding the layers together and forming a smooth, structurally stable board.

| Product Name | Three-layer hot press | Four-layer hot press | Five-layer hot press |

| Nominal Total Pressure | 1600KN | 2000kn | 2000kn |

| Number of Hot Platens | 4 Pieces | 5 Pieces | 6 Pieces |

| Specifications of Hot Platens | 3200*1600*42mm | 2500*1300*42mm | 2600*1300*42mm |

| Unit Surface Pressure | 3.12kg/square centimeters | 6.5kg/square centimeters | 6.15kg/square centimeters |

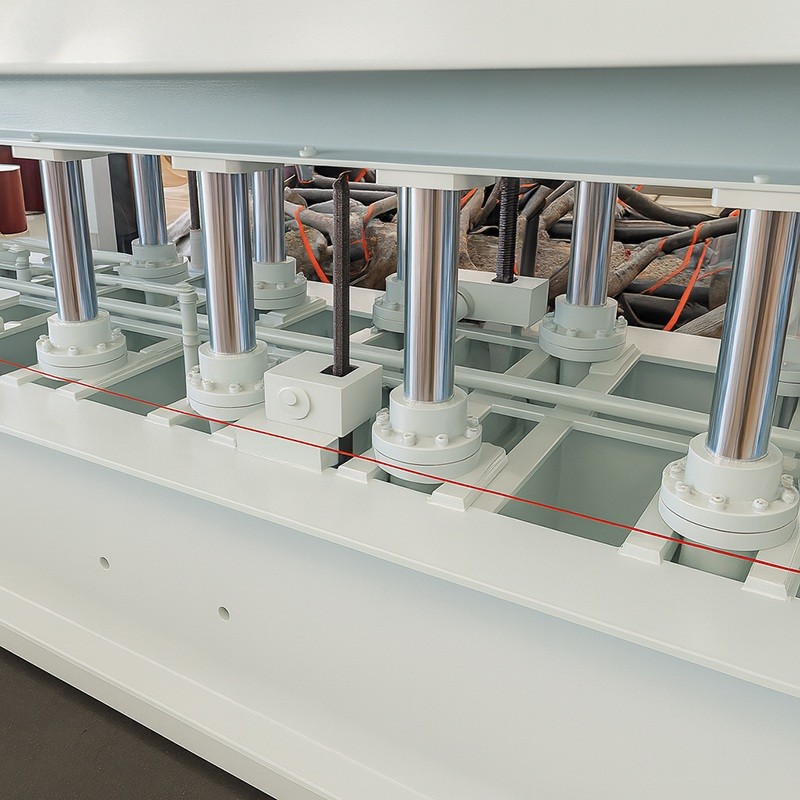

| Number and Diameter of Cylinders | 8 pieces/100mm | 10 pieces/100mm | 10 pieces/100mm |

| Closing Speed | 40mm/s | 40mm/s | 40mm/s |

| Heating Method and Medium | Electric heating medium circulation | Electric heating medium circulation | Electric heating medium circulation |

| Plate Opening Method | Electric | Electric | Electric |

| Gap Between Hot Platens | 100mm | 100mm | 100mm |

| Rated Hydraulic Pressure | 25mpa | 25mpa | 25mpa |

| Cylinder Stroke | 300mm | 400mm | 500mm |

| Installed Power | Hydraulic 7kW, Heating 36kW/Conductive 4kW | Hydraulic 7kW, Heating 36kW/Conductive 1.5kW | Hydraulic 7kW, Heating 36kW/Conductive 4kW |

| Maximum Operating Temperature | 180°C | 180°C | 180°C |

A: The basic process includes Hf Hot Press Machine:

Loading: The glued veneer or board is stacked together.

Heating and Pressing: The machine heats to a set temperature (usually 120–180°C), and a hydraulic cylinder provides the required pressure.

Pressure-Dwelling and Curing: The high temperature and high pressure are maintained for a period of time to fully cure the glue.

Pressure-Relief and Discharging: The pressure is released and the pressed board is removed.

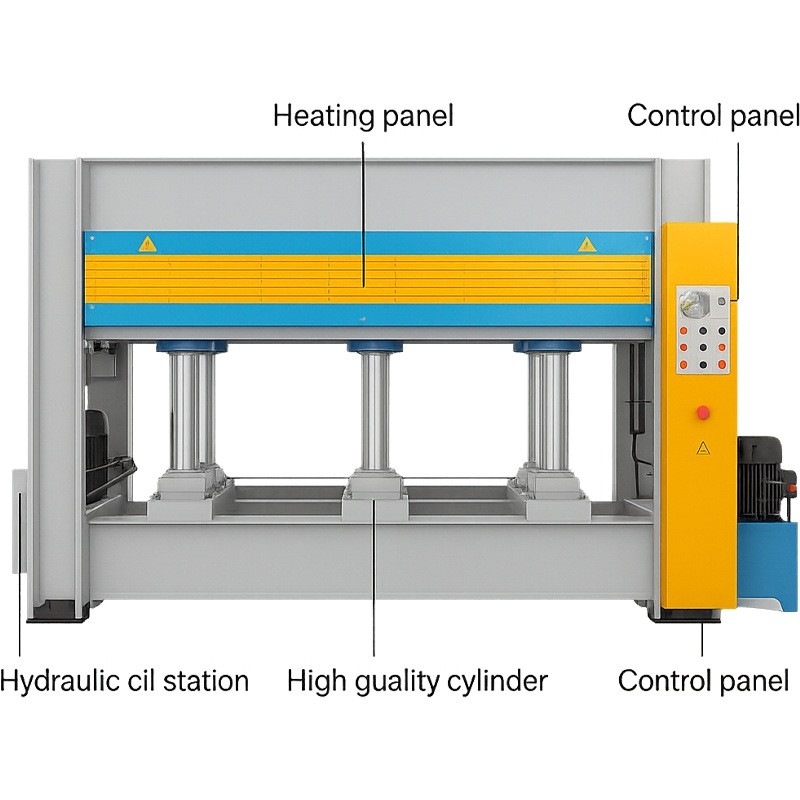

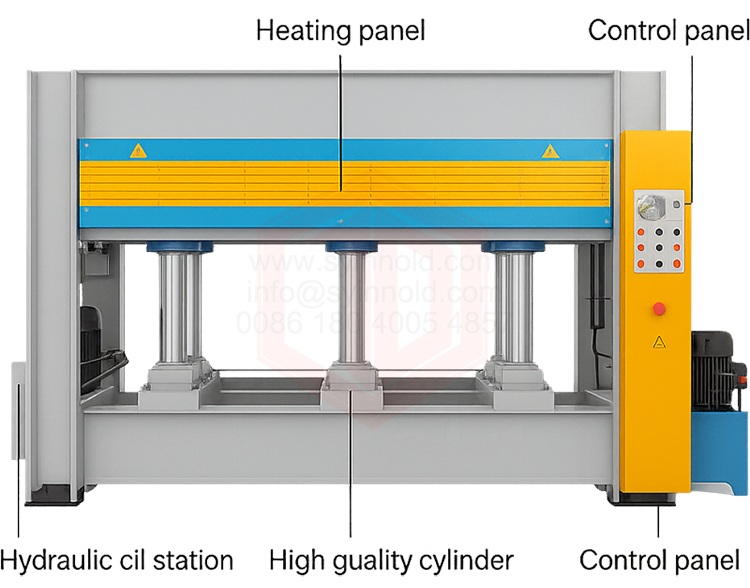

B: Main Components Hf Hot Press Machine

Heating Plate: Conducts heat and ensures uniform temperature.

Hydraulic Cylinder: Provides high pressure to achieve the desired pressing effect.

Control Panel: Sets parameters such as temperature, pressure, and time.

Hydraulic Oil Station: Drives the hydraulic system. Heating System: Common heating methods include electric heating, steam heating, and thermal oil heating.

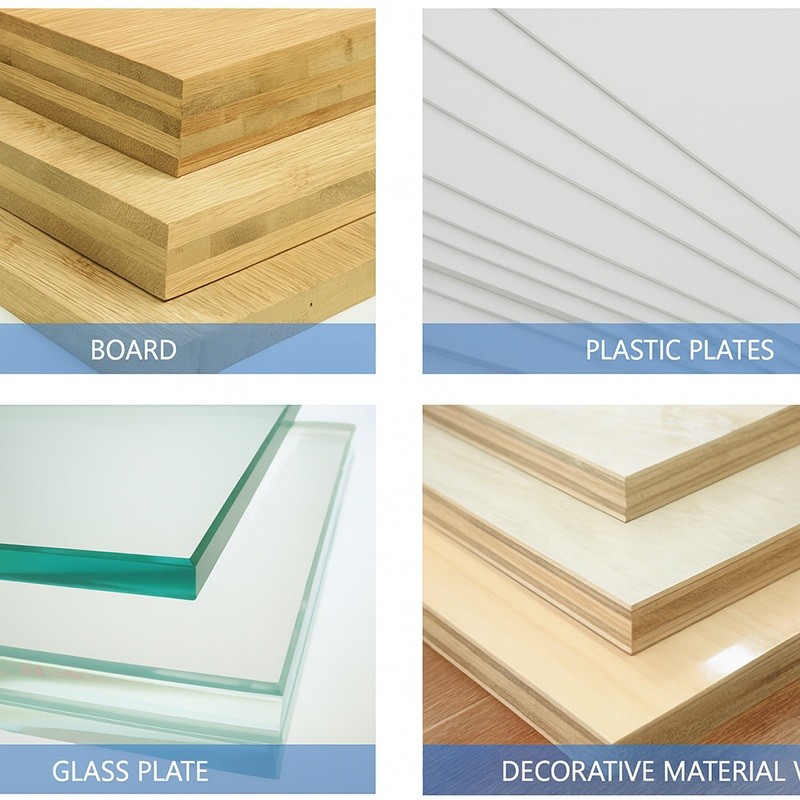

C: Common Applications

Hot pressing of wooden door veneers (composite doors, fire-rated doors);

Laminating of wood-based panels and plywood;

Veneering of furniture and decorative panels;

Laminating of flooring surfaces;

Hot pressing of aluminum honeycomb panels,

electric heating panels,

PVC composite panels, and polyurethane foam panels

D: Equipment Features

Stable pressure and high forming precision;

Uniform heating and strong bonding;

Adjustable temperature and pressure;

High degree of automation,

labor-saving;

Suitable for hot pressing of a variety of materials