How Effective is a Sponge Crushing Machine?

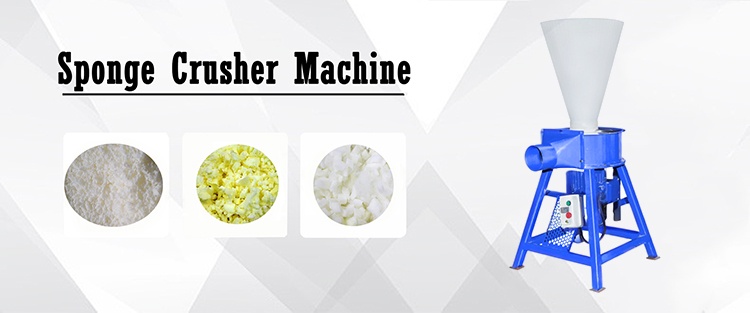

In furniture manufacturing, bedding, packaging, and recycling industries, the demand for high-quality sponge processing equipment has been rising. A reliable Sponge Crushing Machine not only improves efficiency but also ensures that waste sponge and foam are reused effectively. So, how effective is the processing performance of a sponge crushing machine, and why are INNOLD’s machines trusted by so many customers?

1. High Efficiency and Uniform Output

Modern Sponge Crusher Machine and Sponge Shredder Machine are designed to handle large volumes of sponge scraps quickly. With sharp cutting blades and stable motors, the crushed sponge pieces are uniform in size and ready for reuse in pillows, cushions, toys, and packaging.

For smaller factories or workshops, a Small Foam Crushing Machine or Small Foam Shredder provides a compact yet efficient solution. These models save space while maintaining consistent performance, making them ideal for businesses with limited production areas.

2. Flexible Options for Different Applications

Different industries require different processing methods:

The Small Sponge Shredder is suitable for delicate sponge materials where precision matters.

A Sponge Cutting Machine ensures clean slicing of sponge blocks for further processing.

For large-scale recycling, the Sponge Shredding Machine can handle continuous feeding, producing fine and evenly shredded materials.

This flexibility allows manufacturers to choose the right model according to their material type and capacity needs.

3. Quality and Customization by INNOLD

What makes INNOLD machines stand out is not only their durability but also the ability to provide customized solutions. Every factory has unique requirements, whether it is particle size, machine capacity, or workshop layout. INNOLD offers tailored designs to ensure each customer gets the right equipment for their production line.

European standard manufacturing ensures long service life.

High-quality materials and components reduce maintenance needs.

Custom configurations adapt to special production demands.

4. Environmental and Cost Benefits

By using a Sponge Shredder Machine, manufacturers can recycle waste sponge effectively. This reduces raw material costs and minimizes environmental impact, making production both economical and eco-friendly.

5. Conclusion

The processing effect of a Sponge Crushing Machine depends on machine quality and design. From compact models like the Small Foam Crushing Machine and Small Sponge Shredder to industrial solutions such as the Sponge Shredding Machine, INNOLD provides reliable equipment that meets international standards. With proven performance and customized services, INNOLD machines help businesses improve efficiency, reduce costs, and achieve sustainable production.

Post time:2025-09-12