Multi-Needle Quilting Machine Industrial Cnc Multi-Needle Quilting Machine For Textiles

Multi-Needle Quilting Machine Industrial Cnc Multi-Needle Quilting Machine For Textiles

Multi-Needle Quilting Machine Industrial is an industrial sewing machine specifically designed for continuous quilting on materials such as woven fabrics, interlayer cotton, and non-woven fabrics. It utilizes multiple rows of needles working simultaneously to complete large-area quilting patterns in one go, such as straight lines, wavy lines, and textured lines, significantly improving production efficiency.

| Quilting width | 3250mm |

| Space between needle rows | 76.2,152.4mm |

| Model of needle | 16#, 19# |

| Space between needles | 25.4mm |

| X-axis movement displacement | 304.8 |

| Thickness of quilting | 80mm |

| Stitch length | 3~8mm |

| Speed of operation | 20~120m/h |

| Thickness of quilting | ≤25mm |

| Quilting speed | 200-900 RPM |

| Voltage | 380V/50HZ、220V/60HZ |

| Gross weight | 4500KG |

I. Working Principle of Multi-Needle Quilting Machine Industrial:

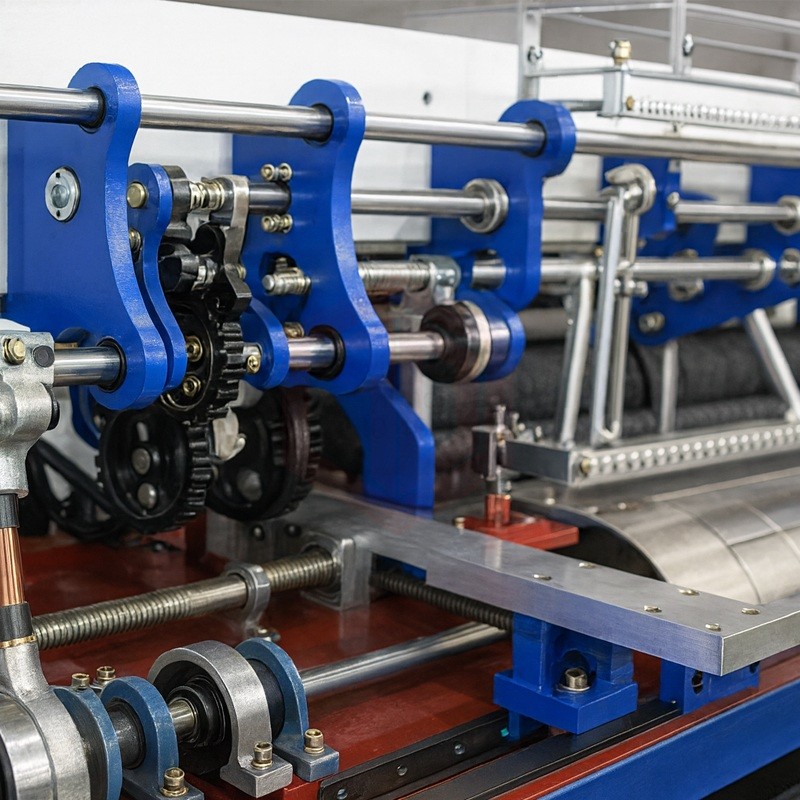

A multi-needle quilting machine consists of an upper thread system, an lower thread system, a needle row, a presser foot mechanism, a feeding mechanism, and a computer control system.

When the machine is running, multiple sewing needles, under synchronized control, pierce the fabric and filling layer at high speed. The upper and lower threads interweave to form stitches, creating stable and aesthetically pleasing quilting patterns.

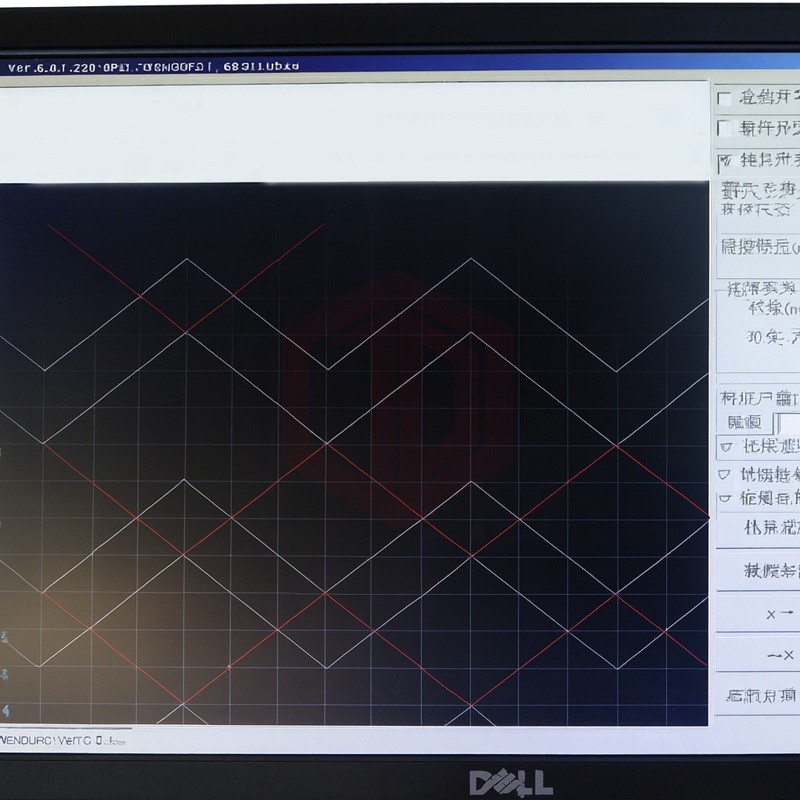

Modern multi-needle machines are often equipped with servo motors and computer control systems, allowing users to directly set parameters such as pattern, stitch length, and speed on a touchscreen.

II. Main Types of Multi-Needle Quilting Machine Industrial:

Mechanical Multi-Needle Quilting Machine Uses cam or linkage drive.

Lower price, but patterns are fixed and adjustments are inconvenient.

Computer-Controlled Multi-Needle Quilting Machine

Uses a servo control system, allowing for free pattern programming.

It can store multiple pattern files and achieve automatic switching.

High quilting precision and high speed, suitable for the high-end mattress, home textile, and apparel industries.

III. Main Application Industries:

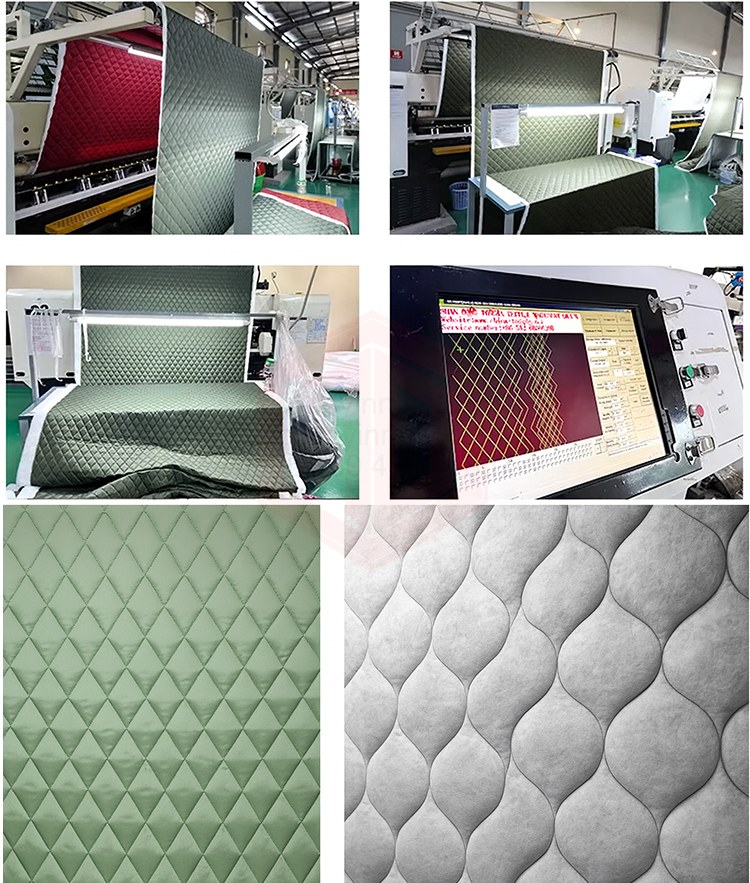

Mattress Industry: Quilting and binding of mattress fabrics.

Home Textile Industry: Quilting decoration for quilts, bedspreads, pillowcases, etc.

Apparel Industry: Jacket, down jacket linings, thermal clothing fabrics.

Automotive Interior Industry: Seat, door panel, floor mat decorative lines.

IV. Equipment Features and Advantages

High production efficiency due to simultaneous multi-needle operation; High precision computer control with automatic deviation correction; Quick pattern file change capability; Stable operation, low noise, and easy maintenance; Uniform quilting stitches, clear patterns, and aesthetically pleasing results.