Wood Surface Finishing Machine Belt Oscillating Sander Disc Combo Wood Sanding Machine

Wood Surface Finishing Machine Belt Oscillating Sander Disc Combo Wood Sanding Machine

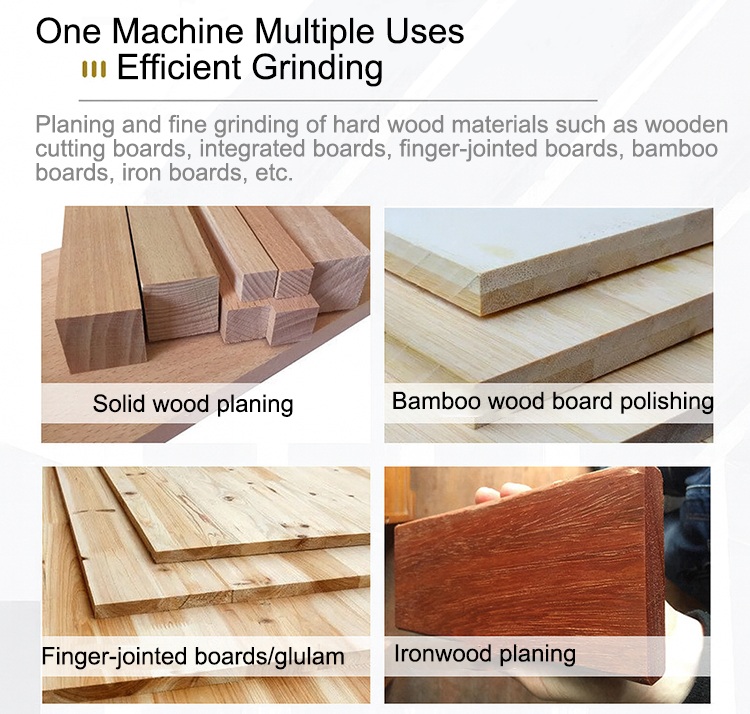

Wood Surface Finishing Machine is a mechanical device that planes and smoothes wood surfaces. It's a key piece of equipment used in industries like wood processing, furniture manufacturing, and flooring production. It's like a combination of a planer and a sander, capable of achieving thickness, smoothing, and finishing in a single operation.

| Specifications | D-RP630 | D-RP1000 | D-RP1300 |

| Working Width | 630mm | 1000mm | 1300mm |

| Working Thickness | 2-200mm | 2-200mm | 2-120mm |

| 1# Sanding Belt Speed | 18m/min | 18m/min | 18m/min |

| 2# Sanding Belt Speed | 14m/min | 12m/min | 12m/min |

| Conveyor Belt Height | 5-25m/s | 5-25m/s | 5-25m/s |

| Sanding Belt Dimensions | 650*1920mm | 1020*2020mm | 1320*2020mm |

| Total Motor Power | 20.37-35.37kw | 20.77-38.87kw | 56.55-75.55kw |

| Stroke Height | 120-200mm | 120-200mm | 120-200mm |

| Operating Air Pressure | 0.5Mpa | 0.6Mpa | 0.6Mpa |

| Suction Air Speed | 25m/s | 25m/s | 25m/s |

| Suction Air Volume | 5000m³/h | 5000m³/h | 5000m³/h |

| Dimensions | 1700*1100*2050mm | 1700*1400*2050mm | 2700*2200*2050mm |

| Net Weight | 1000kg | 2000kg | 3000kg |

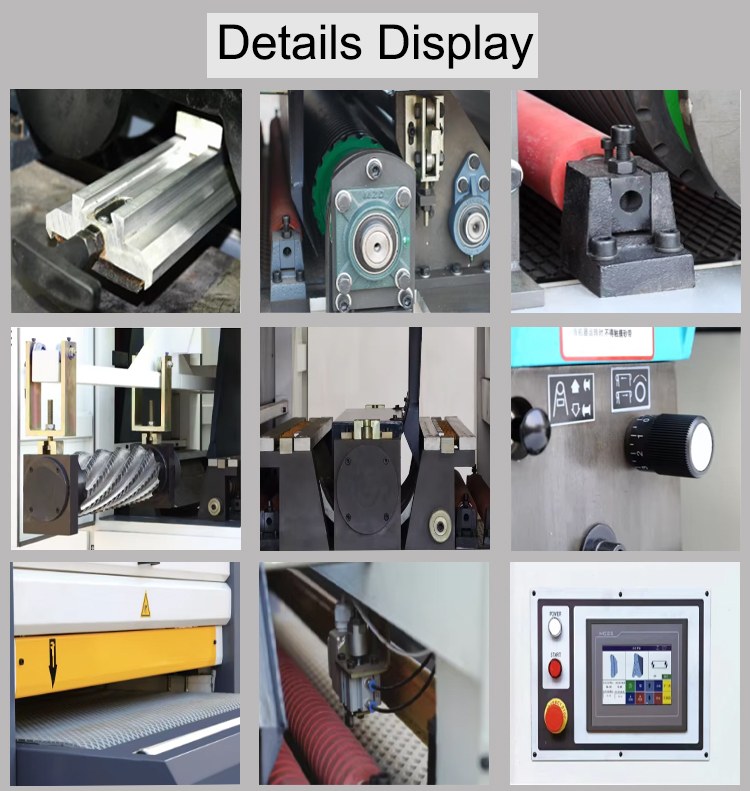

Features of Wood Surface Finishing Machine:

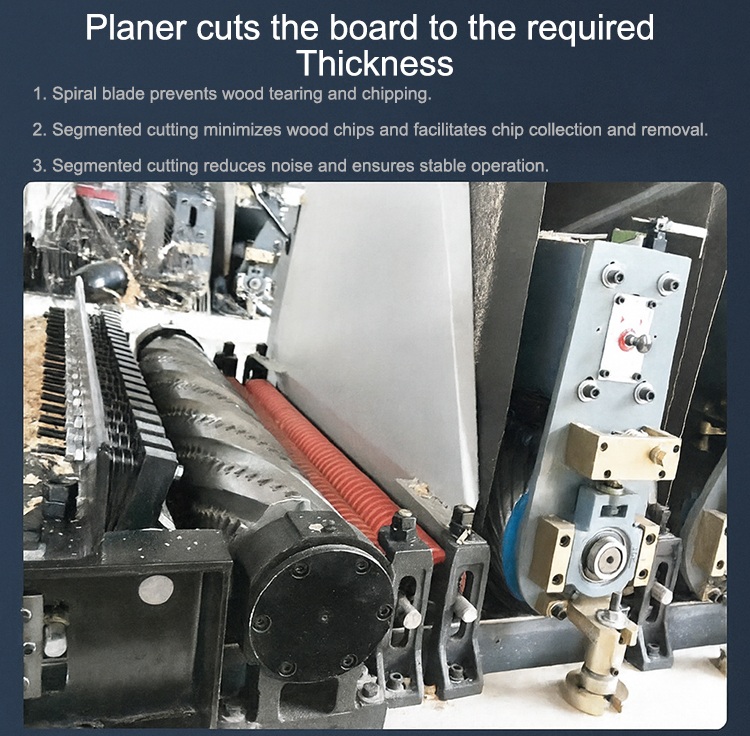

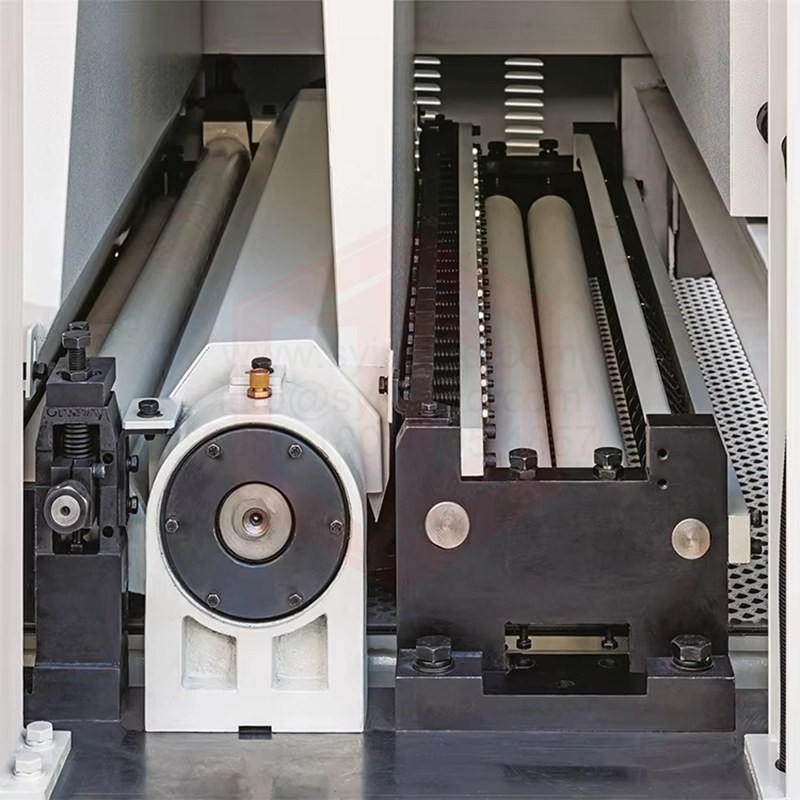

1. The planer is a sanding machine specifically designed for solid wood paneling. The planer shaft utilizes a 15mm x 15mm German-made Tiger Head blade, which is the most commonly used internationally. It features high-efficiency and wear-resistant blades. The conveyor utilizes a frequency converter, ensuring global service and stability. This is a strong, anti-interference feature.

3. The support utilizes a cast iron structure for stable pressure and deformation, ensuring precise sanding and a perfect sanding effect.

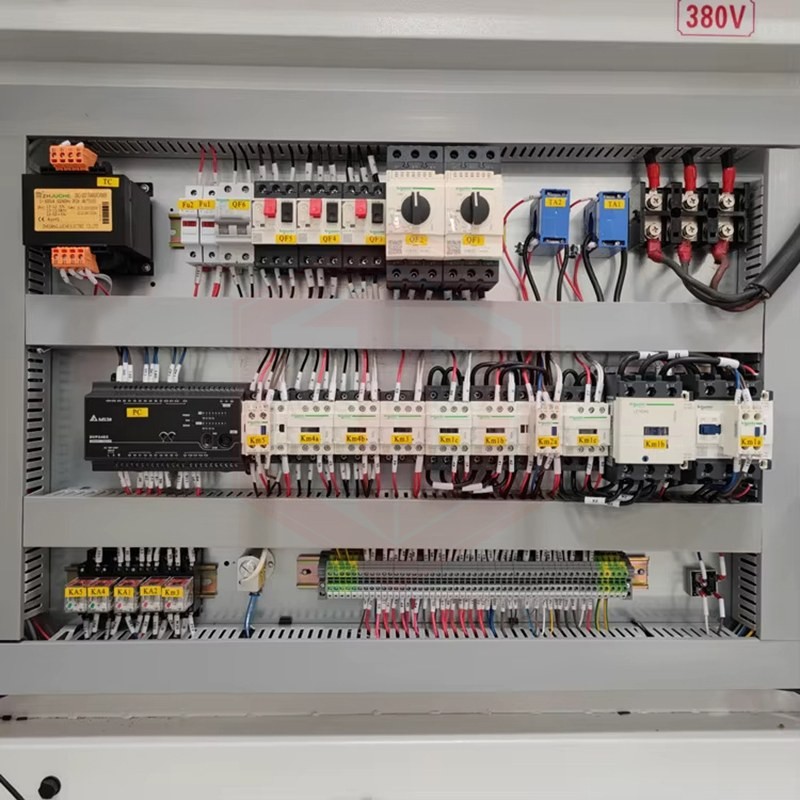

4. The main electrical components are genuine Chint brand components, ensuring stable operation.

5. The machine utilizes imported planer rollers, calibrating rollers, and soft rubber rollers (or a combination sanding frame). The planing, sanding, and polishing process is highly efficient and energy-efficient.

6. A casting backstop prevents the board from rebounding and injuring personnel during processing.