Wool Glove Knitting Machine Computerized Good Price Industrial Glove Making Machine

Wool Glove Knitting Machine Computerized Good Price Industrial Glove Making Machine

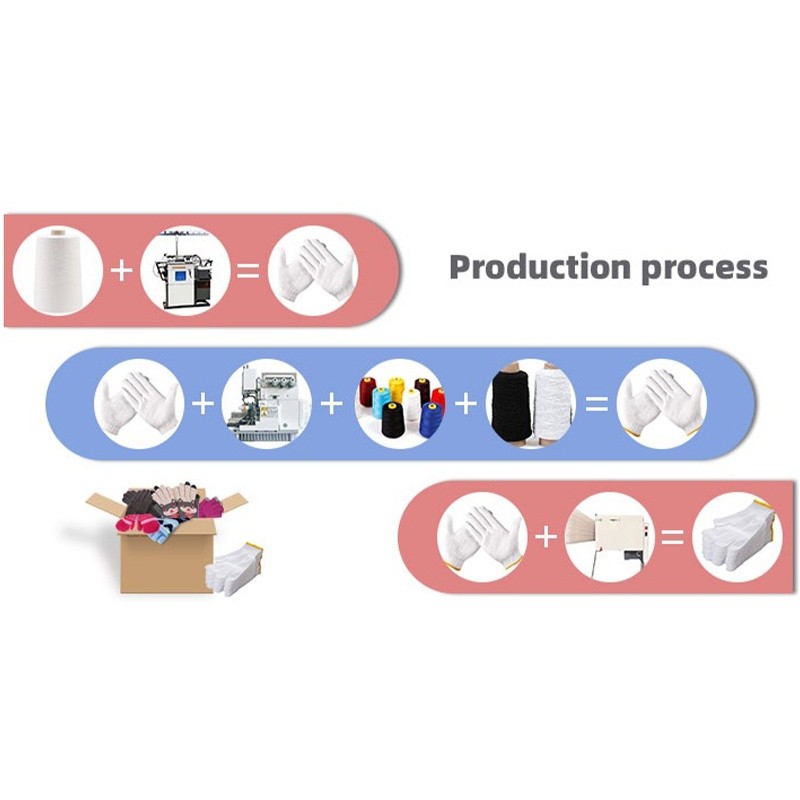

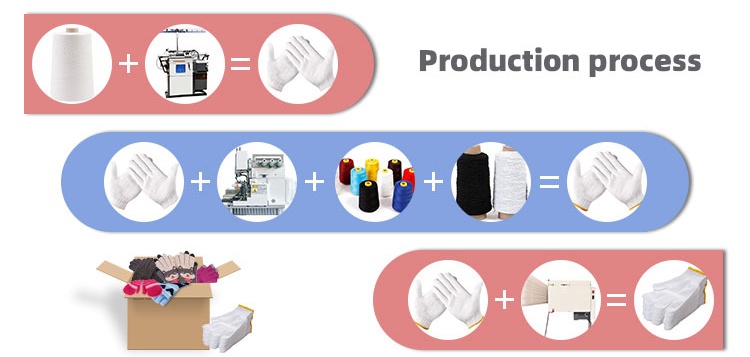

The Wool Glove Knitting Machine adopts a high-quality sinker knitting system, equipped with high-quality materials and exquisite processing and assembly technology. The electronic control system is stable, simple and easy to operate. It is equipped with automatic stop protection devices such as yarn breakage, poor fabric falling, counting, motor overload, etc. to increase the yield of finished products. Wool Glove Knitting Machine is suitable for a wide range of raw materials, mainly knitting full-finger, half-finger, and covered-finger cold-proof and warm gloves, and can also knit thin labor protection gloves for construction sites and factories.

| Model Number | IN-G305 | |||

| Size | 7G | 8G | 10G | 13G |

| L:46 | L:52 | L:63 | L:88/89 | |

| M:42 | M:48 | M:58 | M:83/84 | |

| S:53 | S:78 | |||

| Capacity | 360pairs/24h | 300pairs/24h | 280pairs/24h | 180pairs/24h |

| See Probability | 15-35set/ one people | 22-55set/one people | ||

| Power | Single-phase 220v/300w,or Three-phase:220v/250w | |||

| Abnormity Stop | Broken Yarn,Poor dropping,overloading of motor,bump of needles,low battery,wrong direction | |||

| Knitting Speed | Finger:300r/m,Palm:300r/m | Finger:240r/m,Palm:240r/m | ||

| Machine Size | 1230*650*1750mm | |||

| Packaging Size | 1300*500*1250mm | |||

| Net Weight | 210kg | |||

Product features Wool Glove Knitting Machine:

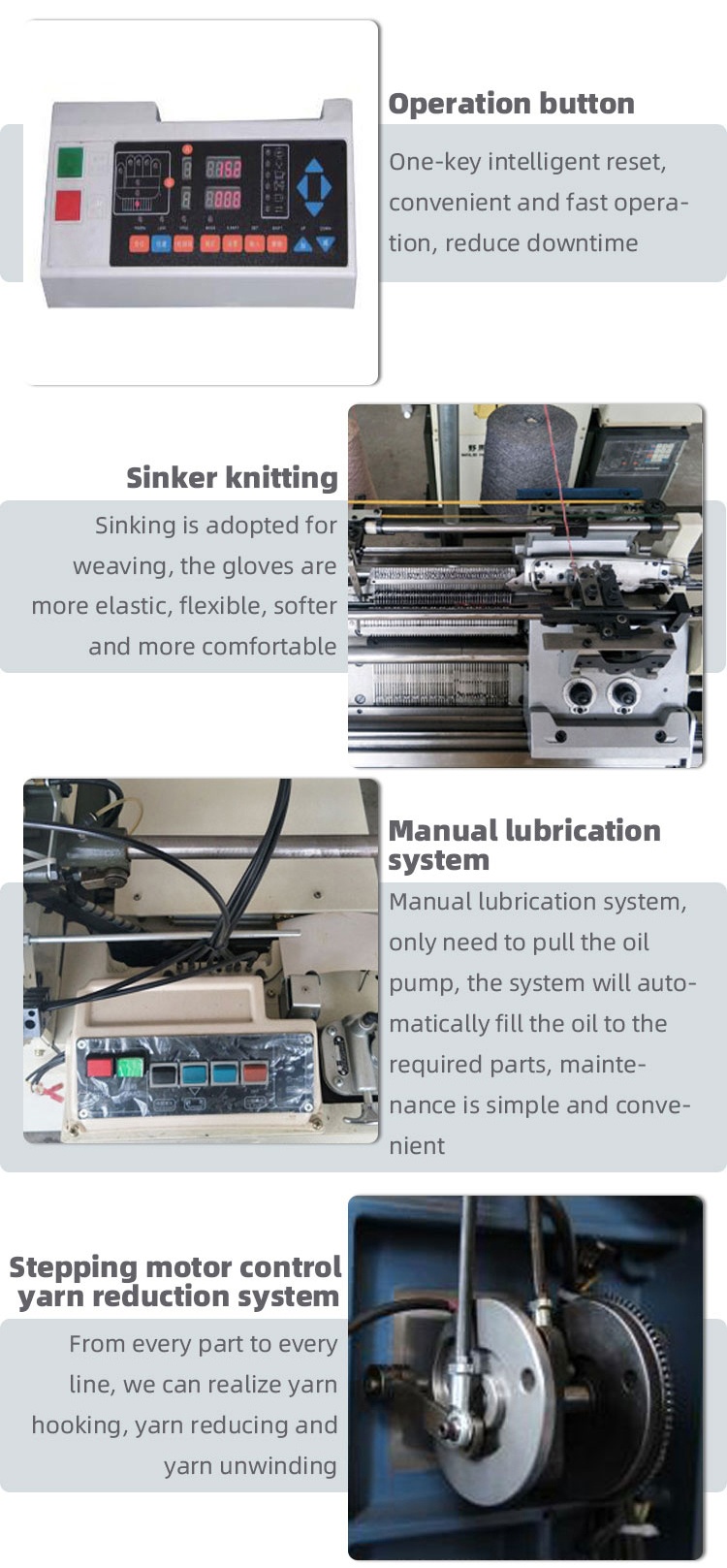

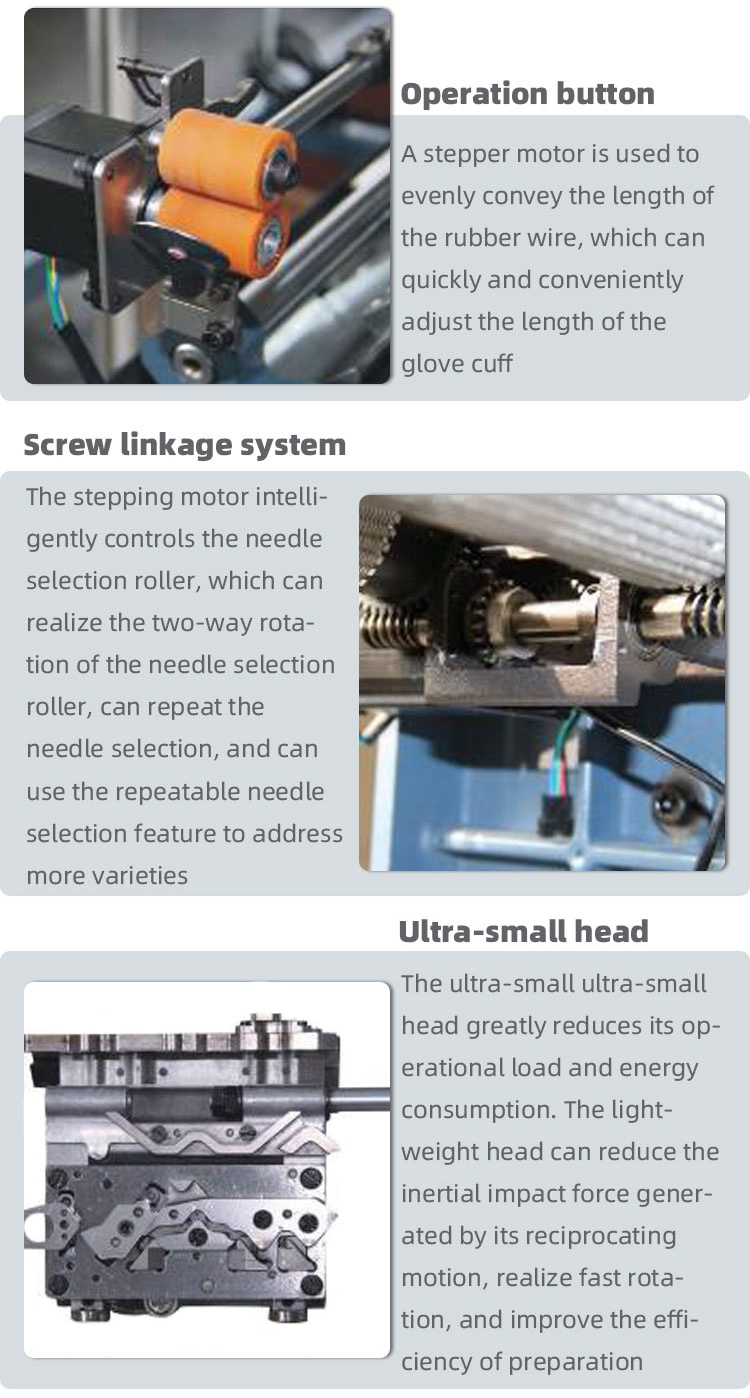

1. The use of sinkers for weaving makes the gloves more elastic, tough, softer and more comfortable.

2. The jet device sprays dust at the right time, and the woven gloves are more imposing and classy.

3. The control keyboard is mainly aimed at easy operation, such as the display screen showing the data status of the machine in different states when it is running.

4. The manual centralized lubrication system only needs to pull the oil pump, and the system will automatically inject oil to the required parts, which is easy to repair and maintain and improves productivity.

Maintenance and maintenance Wool Glove Knitting Machine:

In order to make the Wool Glove Knitting Machine run normally, reduce the appearance of defective products, improve machine efficiency, and keep the machine clean, it is very important to refuel on time.

Note: When performing overall maintenance of the machine, be sure to cut off the power supply.

1. The needle plate and sinker seat are most likely to accumulate dust. If they are not cleaned in time, it will have adverse effects.

2. Please use an air gun to blow away the fiber scraps and other dust on the needle plate and other parts every 8-12 hours.

3. The air filter should be checked once a week to remove the dirt inside.

4. Clean the oil pump once a year with a cleaning agent.

5. Refuel every 8-12 hours.