Cotton Feeding Machine Hot selling For Fiber Opening Machine

Cotton Feeding Machine Hot selling For Fiber Opening Machine

This automatic Cotton Feeding Machine is primarily used for the automatic feeding and pretreatment of fluffy materials such as polyester fibers, PP cotton, and hollow fibers, providing a stable and uniform supply of raw materials to downstream opening and filling machines.

| Model | IN005F | IN005F1 | IN005F2 |

| Capacity | 60-200kg/h | 60-300kg/h | 30-120kg/h |

| Air Pressure | 0.6-0.8Mpa | ||

| Voltage | Customized | ||

| Power | 1.85kw | 2.95kw | 2.95kw |

| Size | 2200*1600*2100mm | 5800*1600*2100mm | 2000*1000*1700mm |

| Weight | 300kg | 450kg | 380kg |

| Other Production Quantities can be customized | |||

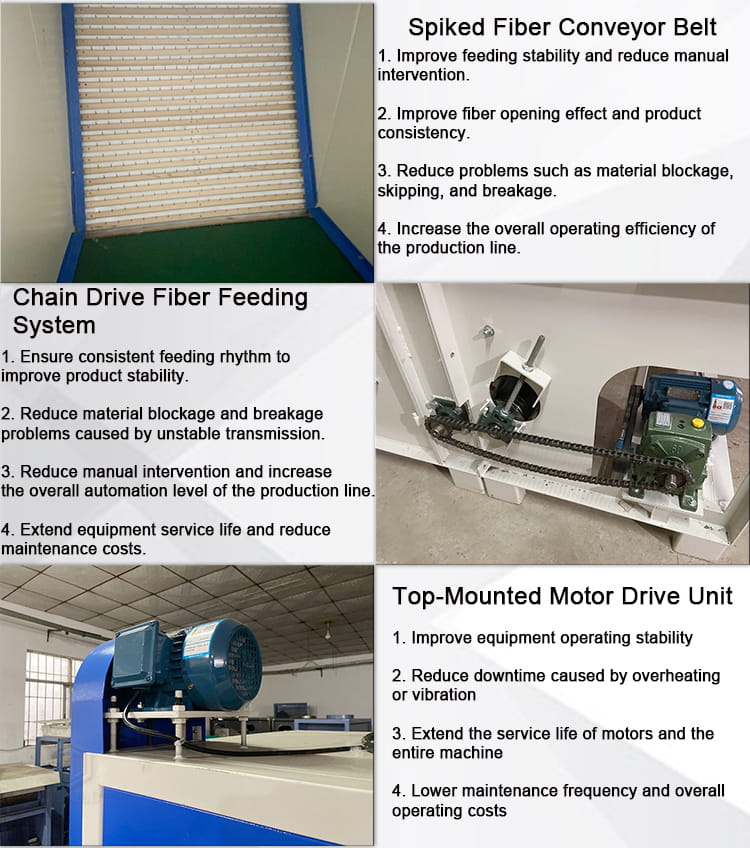

Structure and Working Principle Cotton Feeding Machine:

1. Fibers are fed into the feeding chamber.

2. Internal feeding walls and rollers evenly distribute the fibers.

3. A chain drive system controls the feeding speed.

4. An independent motor system ensures continuous operation.

5. The fibers are smoothly transported to the next processing unit.

Through a rational structural layout and transmission design, common problems such as clumping, blockage, and uneven feeding are effectively avoided.

Core Structural Advantages Cotton Feeding Machine:

1. Ample feeding space reduces the need for frequent refilling.

2. Ensures loose and free-flowing fibers.

3. Stable feeding rhythm, reliable operation, and long service life.

4. Stable power output, suitable for long-term continuous operation.

5. Reduces dust spillage and improves operational safety.

Applicable Raw Materials:

1. Polyester fiber

2. Hollow crimped fiber

3. PP cotton

4. Recycled fiber

5. Other fluffy and soft fibers

Application Industries of Cotton Feeding Machine:

1. Pillow and cushion production

2. Toy filling factories

3. Fiber opening and processing production lines

4. Home textile manufacturing

5. Fiber recycling systems

Value for Customers of Cotton Feeding Machine:

1. Improved feeding stability and enhanced downstream fiber opening effect.

2. Reduced manual intervention and lower labor costs.

3. Reduced risk of equipment blockage and downtime.

4. Increased automation level of the entire production line.

5. Higher product consistency and more stable quality.