Door Cold Press Machine Single Daylight Frame-Type Cold Press For Door Skin Lamination

Door Cold Press Machine Single Daylight Frame-Type Cold Press For Door Skin Lamination

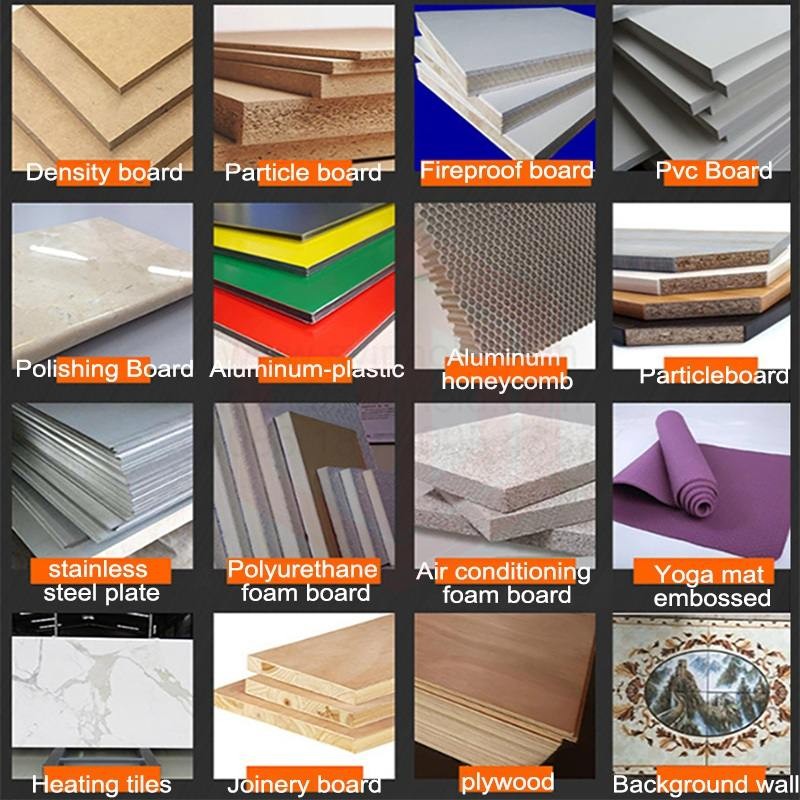

Door Cold Press Machine is a machine used for pressing, veneering, and shaping wood panels. It utilizes high pressure generated by a hydraulic system to tightly press together multiple layers of wood, veneer, or veneer material at room temperature, achieving a strong bond and smooth surface. It is a crucial piece of equipment in the woodworking industry, including furniture manufacturing, panel furniture, door panels, flooring, and building formwork.

| Model | I-C2510 | I-C2512 | I-C2515 | I-C3010 | I-C3012 | I-C3015 |

| Platen size | 1250*2500mm | 1250*2500mm | 1250*2500mm | 1250*2500mm | 1250*2500mm | 1250*2500mm |

| Stroke | 1000mm | 1200mm | 1500mm | 1000mm | 1200mm | 1500mm |

| Pressure | 50T | 50T | 50T | 50T | 50T | 50T |

| Opening distance | 1000mm | 1200mm | 1300mm | 1300mm | 1300mm | 1500mm |

| Power | 4.0kw | 4.0kw | 4.0kw | 4.0kw | 4.0kw | 4.0kw |

| Machine Size | 2910*1250mm | 2910*1250mm | 2910*1250mm | 3410*1250mm | 3410*1250mm | 3410*1250mm |

| Weight | 1800kg | 2000kg | 2200kg | 2000kg | 2200kg | 2400kg |

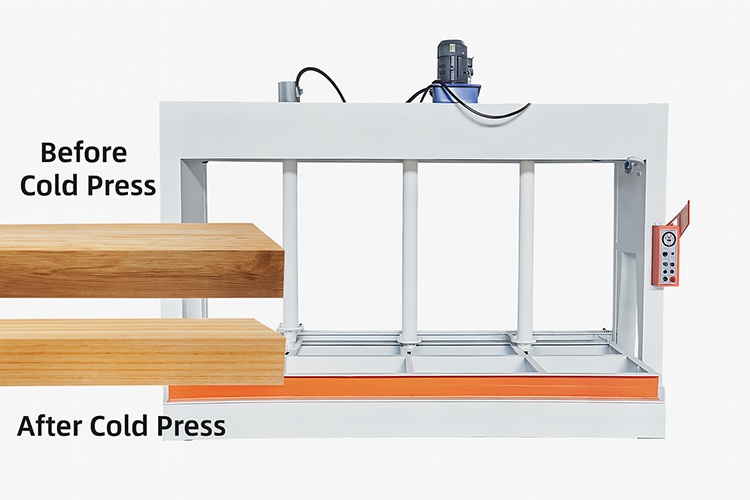

Working Principle Door Cold Press Machine:

A wood cold press uses a hydraulic cylinder to push the press plate up and down, applying pressure to the wood veneers placed on the machine's worktable. This allows the glue to fully cure at room temperature, achieving initial bonding and shaping of the veneers.

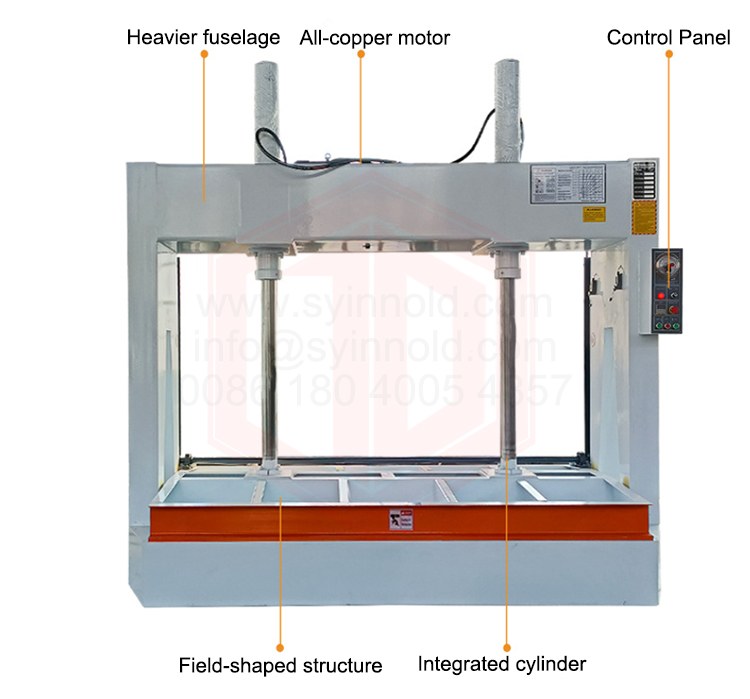

It typically consists of the following components:

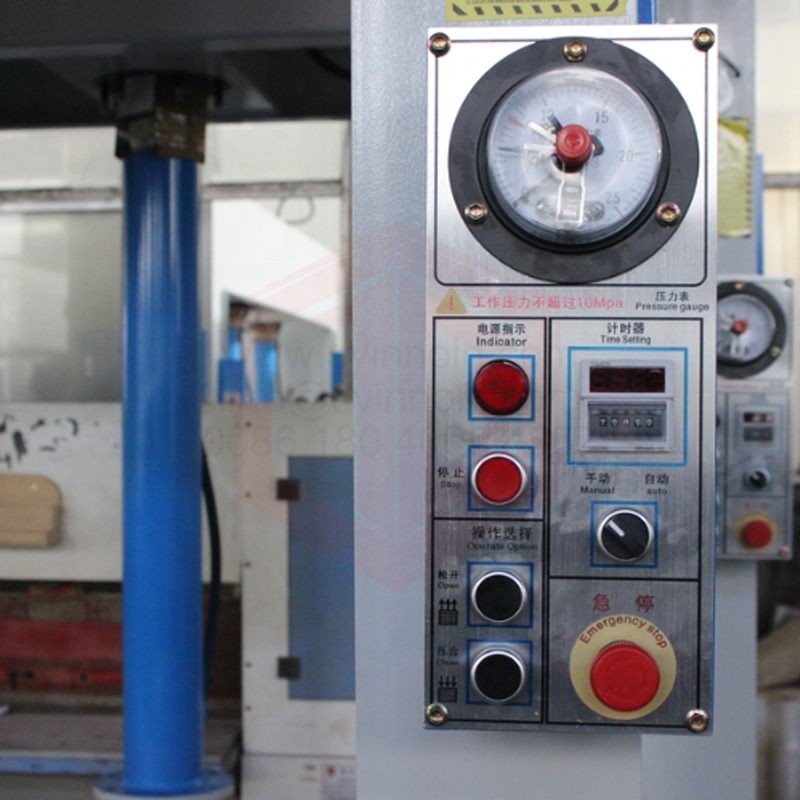

Hydraulic system (generates and controls pressure)

Steel frame/press plate system (provides a load-bearing platform)

Electrical control system (controls lifting and lowering, timing, and pressure maintenance)

Worktable and guide system (ensures uniform pressure and parallelism)

Main Functions Door Cold Press Machine:

Lamination and bonding: Presses multiple layers of veneer or sheet material into a single sheet.

Thickness setting: Controls sheet thickness and maintains flatness.

Veneer pre-pressing: Pre-bonds the veneer before hot pressing to reduce air bubbles and improve bonding quality.

Gluing and fixing: Helps the cold-curing glue achieve initial set under pressure.

| Common types | |

| Name | Features |

| Single Layer Cold Press | Suitable for processing ordinary wood or veneer materials |

| Multi-Layer Cold Press | Improves production efficiency and is suitable for mass production |

| Frame Type Cold Press | Stable structure and uniform force distribution |

| Four-Post Cold Press | High precision and excellent parallelism |

| Hydraulic Cold Press | Powerful power and adjustable pressure |

| Automatic Cold Press | Automatic lifting and timing control system |

| Item | Cold Press | Hot Press |

| Operating Temperature | Room Temperature | High Temperature (100–150°C) |

| Function | Initial pressing, shaping, and pre-pressing | Gluing and curing, final product shaping |

| Energy | Low | High |

| Applicable Glues | Cold curing glue, white latex, etc. | Heat curing adhesive |

| Cost | Low | High |