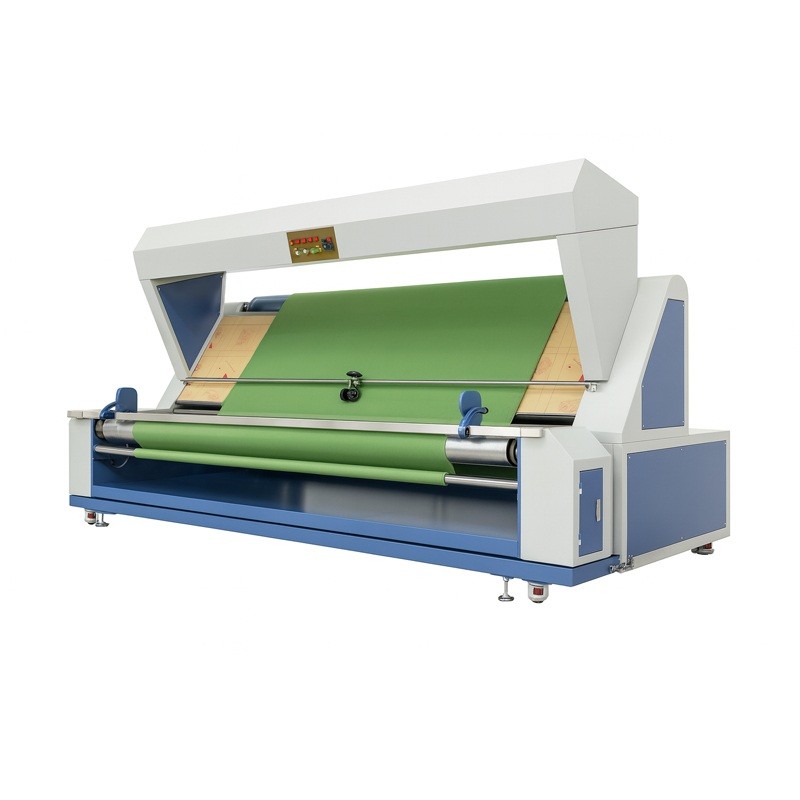

Fabric Inspection Line Durable Machine Body Curtain Mesh Fabric Inspection Machine

Fabric Inspection Line Durable Machine Body Curtain Mesh Fabric Inspection Machine

Fabric Inspection Line is an automated device specially used for inspecting, measuring and winding cloth. It is mainly used in the production process of textile, clothing, home textile, non-woven fabric and other industries. It uses photoelectric sensors, camera recognition systems or manual auxiliary inspection to automatically inspect, record and organize the surface quality of cloth after production.

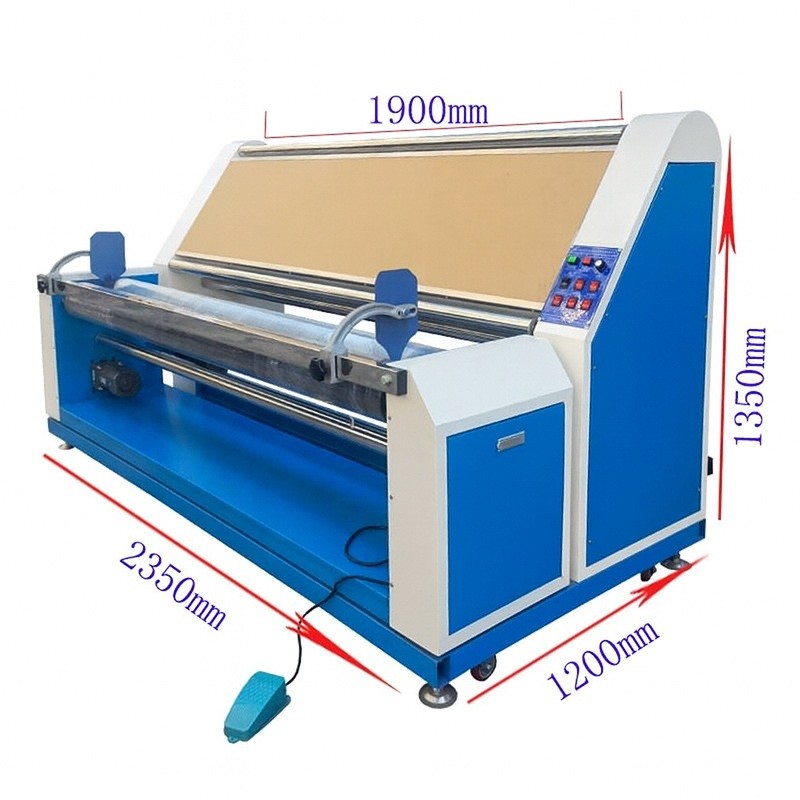

| Voltage | 3P, 220V/380V |

| Roll width | 1900mm |

| Processing speed | 0-60Y/ min |

| Power | 1KW |

| Machine size | 2350*1200*1350mm |

| Machine weight | 260kg |

Basic Functions of the Fabric Inspection Line

1. Fabric Inspection

Automatically detects fabric defects such as color difference, holes, stains, weft skew, and yarn skipping.

2. Automatic Length and Weight Counting

A built-in high-precision length counting system automatically calculates fabric length or weight, eliminating manual measurement errors.

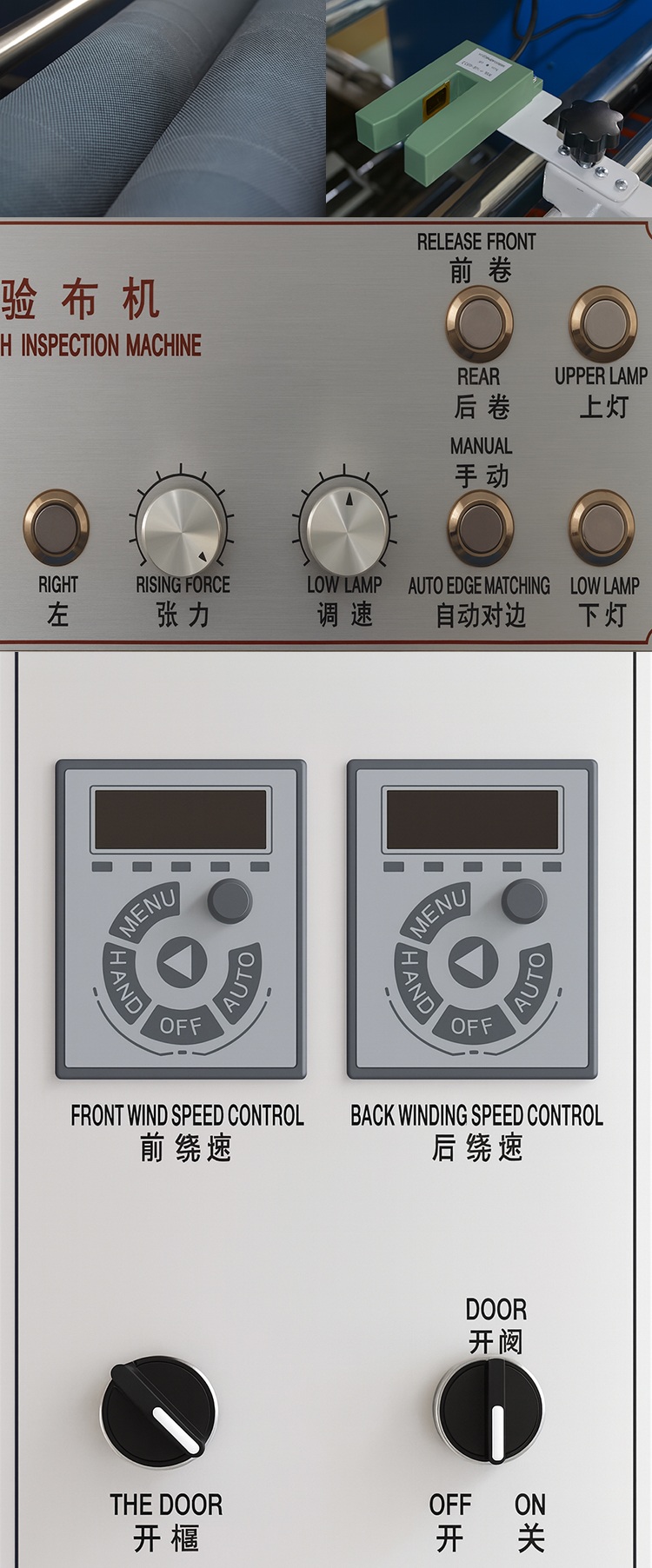

3. Automatic Edge Alignment

Using infrared or photoelectric sensing, the fabric edge is automatically corrected for neat and beautiful fabric rolls.

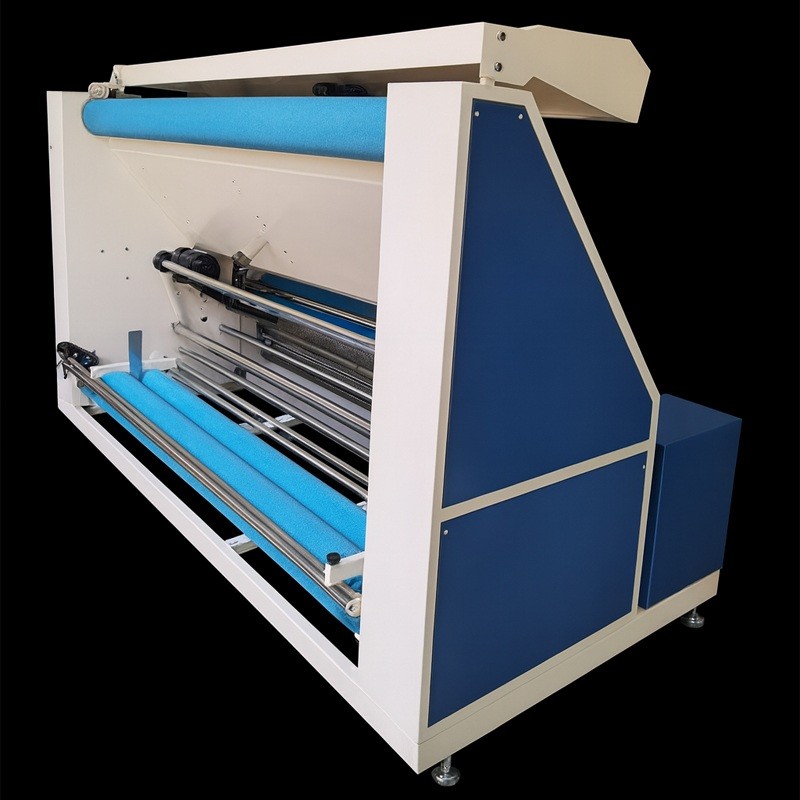

4. Automatic Winding and Rewinding

After inspection, the fabric can be automatically wound or rewound, facilitating packaging, storage, and further processing.

5. Light Source Inspection

Equipped with upper and lower light sources, it easily detects subtle surface defects, especially suitable for dark or dense fabrics.

Main Advantages of Fabric Inspection Line

1. Improved Work Efficiency

Automated fabric inspection machines enable continuous fabric inspection, automatic fabric winding, and automatic machine shutdown, significantly increasing fabric inspection speed.

Compared to manual inspection, this machine boasts efficiency improvements of over 2-3 times, making it particularly suitable for high-volume textile and garment factories.

2. High Inspection Accuracy

Equipped with a photoelectric sensor system or camera recognition system, the machine automatically detects defects, stains, color variations, and holes on the fabric surface, ensuring more uniform and stable inspection and preventing manual errors.

3. Automatic Edge Alignment and Straightened Fabric Rolling

Equipped with an automatic edge alignment device, the machine ensures smooth and uniform fabric rolls, effectively reducing waste and subsequent cutting errors.

4. Reduced Labor Costs

One automatic fabric inspection machine can replace 2-3 workers, significantly reducing labor costs and workload.

5. Compatible with a variety of fabric types

Compatible with a wide range of materials, including cotton, knitted fabrics, denim, synthetic fabrics, non-woven fabrics, and coated fabrics, it offers simple adjustments and high versatility.

6. Data Recording and Intelligent Management

Some high-end models feature functions such as length and weight counting, and defect logging. They can be connected to ERP or MES systems for digital production management.

7. Stable, Durable, and Easy to Maintain

The machine boasts a sturdy structure, smooth operation, and imported motors and control components for low noise, long life, and easy operation and maintenance.

Applicable industries:

Textile fabric manufacturers

Garment processing factories

Home textile product manufacturers

Non-woven and industrial fabric production lines