How To Use The Fiber Doll Filling Machine?

The Fiber Doll Filling Machine is an automated devices that integrates cotton opening, communicating and filling. It can inject polyester fiber cotton, PP cotton and other filling materials into plush toys, sofa cushions, pillows, pillow cores and other products at a consistent speed.

In production scenarios such as toy factories and home textile factories, this devices can enhance filling efficiency, save labor costs, and make the product feel soft and fluffy.

For merchants who want to participate in this industry and broaden their scale, the fiber doll filling machine has crucial production value and competitive advantages.

Appropriate actions for using the cotton filling maker

When utilizing the fiber doll filling maker, you need to follow the process step by step to ensure the filling quality. The main steps include:

Ecological examination and start-up: Examine that the workplace is dry and aerated, and the machine is positioned horizontally. Before starting, switch on the exhaust system and check that its air intake is normal; clean the conveyor belt and devices debris. After verifying that there is no abnormality, press the power start button and observe the operation to guarantee that the feeding belt remains in the proper instructions (towards the inside of the device).

Cotton product opening: Put the cotton product to be used into the Opening Machine for breaking up. The opening device can loosen the fiber cotton balls to form fluffy and uniform fiber flocs, minimizing obstruction and heap throughout the subsequent filling process.

Feeding and filling amount setting: The loosened cotton product is fed into the filling maker through the communicating gadget. According to the size of the item, set the filling quantity on the control board (managed by the filling time or inflation pressure). The longer the filling time or the greater the air pressure, the more cotton is injected. Users can flexibly change the filling time and air pressure according to the specs of the doll or pillow to achieve the perfect filling result.

Filling and loading operation: Put the opening of the product to be filled on the nozzle of the filling maker and fix it. Step on the filling foot switch, and the device starts to blow the fiber cotton into the doll through the air flow. When filling the cotton, you can observe the external shape and touch sensation, adjust or repeat the operation in time to make sure that the inner material is consistent and full.

Completing cleaning: After filling, release the cotton filling button, remove the completed product and perform completing work such as sealing and stitching. Extra cotton filling can be carried out on unfilled parts. Finally, tidy the equipment: switch off the machine, clean the nozzle and pipeline residual cotton, tidy the machine body and lube the parts on time to guarantee stable operation of the device.

Typical faults and countermeasures

Insufficient cotton: If the item filling seems light, it might be that the cotton supply is insufficient or the cotton filling quantity is set too low. At this time, you can include cotton, extend the cotton filling time or increase the inflation pressure. Make certain the cotton product is loose and dry to help totally fill.

Nozzle clog: After long-term use, the nozzle is prone to fiber accumulation, leading to poor cotton discharge. When obstructed, the machine ought to be stopped, and the nozzle ought to be cleared of clog with air blowing or sticks, and routinely dismantled and cleaned up. Keeping the working environment dry can reduce obstruction.

Fiber pile: If the fiber agglomerates in the communicating pipeline, it will cause unequal filling. The cotton product should be loosened up to make sure that the raw materials are uniformly loose. Modern cotton filling devices typically have loosening up and drying functions, which can minimize the problem of clumping by drying and dehumidifying.

Equipment abnormality: If the machine vibrates strongly or makes irregular noises, it might be that the internal parts are loose or the voltage is unsteady. The machine must be stopped for evaluation right away and used once again after repair.

Scope of application and suggestion

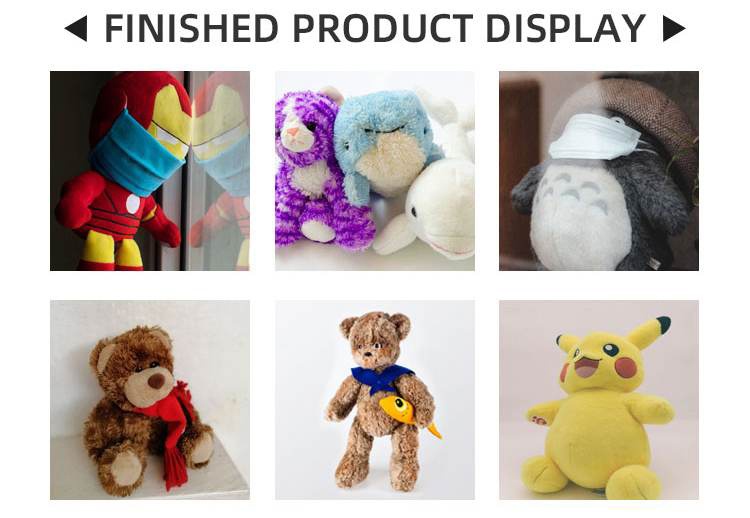

Fiber doll filling devices are suitable for batch processing situations of numerous fiber-filled items. In addition to standard industries such as luxurious toy factories, home fabric factories, and furniture factories, they are likewise extremely suitable for OEM factories, present processing factories, and other companies that have requirements for filling effectiveness. Any celebration where fiber cotton materials require to be injected into soft products (such as pillows, pillows, and toy dolls) can utilize this equipment to enhance production capacity and product quality.

Appropriate operation and maintenance of fiber cotton filling makers can offer full play to their benefits, aid business stably produce high-quality filling items, and improve market competitiveness

Post time:2025-07-28