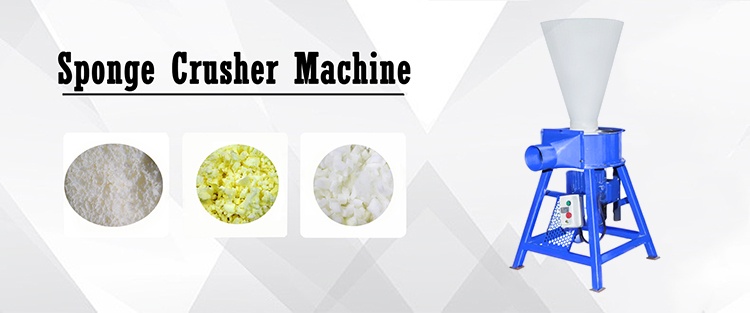

What Are The Advantages Of Sponge Crusher?

In the furniture manufacturing, bed mattress manufacturing, soft toy processing, and sponge recycling industries, Sponge Crushing Machine have come to be important devices for enhancing production performance and decreasing raw material prices. As industry competition magnifies, companies are focusing not only on product top quality however likewise on automation and power performance in production procedures. This post will certainly information the key advantages of sponge shredders to help you choose the ideal devices for your organization needs.

| Model | AB200-4 | AB300-4 | AB400-4 |

| Capacity | 40-50kg/h | 70-80kg/h | 100-120kg/h |

| Size | 680*600*1200mm | 1020*800*1500mm | 1100*500*1400mm |

| Voltage | Customizable | ||

| Power | 4kw | 7.5kw | 11kw |

| Weight | 100kg | 180kg | 350kg |

| Other Capacity can be customized | |||

1. Improving Manufacturing Efficiency

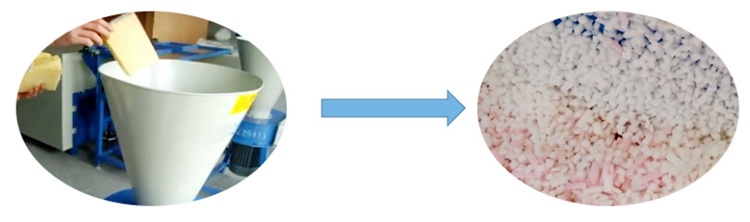

Sponge Shredder Machine make use of high-speed blades or rollers to swiftly cut large pieces of sponge into uniform, little particles. Contrasted to hands-on cutting, effectiveness can be enhanced numerous times, and even 10 times, greater.

Automated Operation: Constant feeding and automated shredding lower hands-on treatment.

Secure Outcome: Ensures a regular per hour processing quantity, making it appropriate for mass production.

2. Saving Raw Material Expenses

Throughout the manufacturing process, sponge scraps and offcuts can not be used straight. Nonetheless, with shredder processing, these scraps can be exchanged recycled sponge particles for usage in pillow cores, sofa dental filling, packaging cushioning, and other applications.

Waste Reuse: Minimizes basic material waste and reduces purchase prices.

Expanded Applications: Recycled particles can likewise be refined right into second processes, creating additional revenue opportunities. 3. Attire Final Product Bit Dimension

Top notch sponge pulverizers are equipped with flexible displays and cutting systems, permitting particle size to be readjusted according to production requirements. This uniform particle dimension not just enhances the look and high quality of recycled sponge products, yet likewise makes certain item convenience and thickness.

4. Easy Procedure and Maintenance

Sponge Cutting Machine feature a straightforward style with a straightforward and intuitive interface, permitting regular employees to take up the task after minimal training.

Quick blade replacement minimizes downtime for upkeep.

Easy-clean framework lowers dust buildup and extends equipment life.

5. Energy Saving and Environmental Management

High-efficiency motors and enhanced transmission structures make certain efficient pulverization while minimizing energy intake.

Low-energy operation decreases manufacturing expenses.

Dirt Decrease: Some designs are equipped with dust removal devices, boosting the production environment and conference environmental requirements.

6. Wide Range of Applications

Sponge Shredding Machine are crucial for manufacturing facilities varying from furniture and cushions to toy and product packaging materials.

Soft sponges: Quickly pulverize without damaging the fiber structure.

High-density sponges: Boosted blades and power systems likewise efficiently procedure high-density sponges.

Post time:2025-08-13