How are Fiber Opening Machines Used in Different Industries?

During our communication with global customers, we often hear this question:

“Are Fiber Opening Machines only suitable for pillow factories? Can other industries use them?”

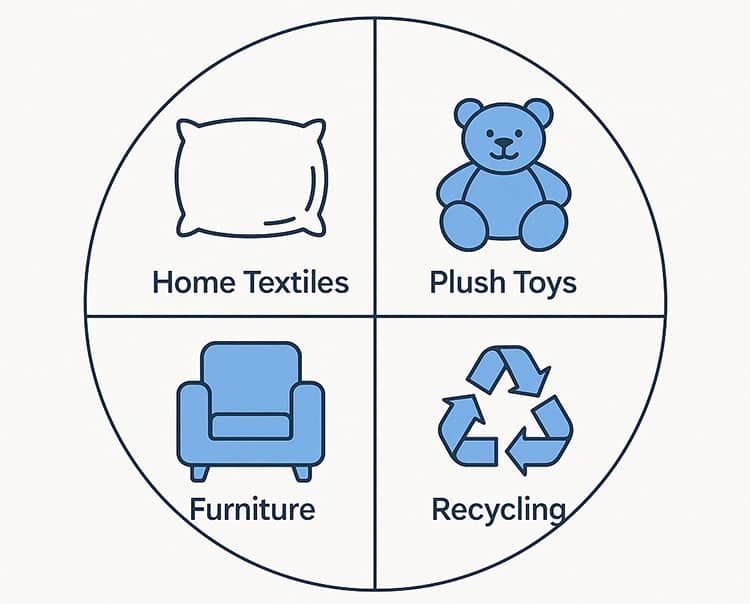

In fact, the applications of fiber opening machines are far broader than many people think. From the home textile industry to toy manufacturing, and even automotive interiors and filter material production, it plays a crucial role in almost all types of flexible fiber processing.

As a factory that has been engaged in fiber equipment manufacturing for a long time, today I want to show you in the most intuitive way how different industries use fiber opening machines.

I. Home Textile Industry: Creating Fluffier and More Comfortable Products

The home textile industry is one of the main users of fiber opening machines.

In the production of pillows, cushions, and quilts, the fiber opening machine can fully loosen the compressed and packaged raw cotton, making it fluffy and uniform.

Applications include:

Pillow filling material opening

Cushion and bolster filling material pretreatment

Quilt fiber fluffing treatment

The benefits of using a fiber opening machine are very obvious: the product feels softer, has better resilience, and the finished product is fuller.

INNOLD's fiber opening machines adopt European standard structural design, resulting in finer opening effects and less dust, making them suitable for high-standard home textile brands.

II. Toy Industry: Making Dolls Fuller and More Lifelike

For plush toy and doll manufacturers, the opening machine is almost an indispensable piece of equipment in the production line.

The loosened hollow fibers are lighter and fluffier, making the doll's shape more three-dimensional.

Application scenarios include:

Processing of internal filling materials for plush toys

Fiber opening for internal filling of dolls and figurines

Internal filling of large cartoon characters

Many toy factory customers have told us:

Since using INNOLD's opening machines, the fullness of the dolls has improved significantly, the appearance is better, the resilience has increased, and the customer complaint rate has decreased.

III. Furniture Industry: Used for Sofa Cushions and Upholstery Filling

The furniture industry also has a great demand for fiber filling, such as sofa backrests, upholstered headboards, and cushions, all of which require the use of opened fibers as internal materials. Applications include:

Sofa cushion filling material opening

Soft furnishing core fiber loosening

Headboard soft furnishing fiber filling treatment

INNOLD's medium and large-sized opening machines support high-volume continuous operation, suitable for the large-scale production needs of furniture manufacturing factories.

IV. Automotive Interior Industry: Used for sound-absorbing cotton and heat-insulating cotton

The automotive industry uses a large amount of fiber materials, such as sound-absorbing cotton for car doors, heat-insulating cotton for ceilings, and sound insulation layers for trunks.

These materials need to undergo fiber opening treatment before being pressed and molded.

For example:

Polyester fiber automotive sound-absorbing materials

Non-woven fabric heat insulation materials

High-density mixed fiber pretreatment

The automotive industry has higher requirements for stability and opening uniformity. INNOLD's industrial-grade opening machines support mixed opening of various materials, suitable for more complex process requirements.

V. Filtration Materials Industry: Improving fiber uniformity and breathability

Before production, filtration materials (such as air filters, purification cotton, smoke filter cotton, etc.) mix various fibers in proportion and then undergo opening to achieve better uniform distribution of the material.

Applications include:

Air filter cotton

Industrial filter core

Dust collector filter material

The role of the opening machine is crucial here:

The more uniform the opening, the higher the filtration efficiency and the longer the material life.

VI. Recycled Fiber Industry: Recycling textiles for reuse

With increasing environmental awareness, more and more companies are starting to use fiber opening machines to process recycled old clothes and fabric scraps for the production of recycled fibers or non-woven fabrics.

For example:

Recycling of old clothing fibers

Opening of fabric scraps

Pretreatment for recycled cotton production

INNOLD can design special roller structures according to the specific materials of the recycling industry, making the opening process more stable and efficient.

Why choose INNOLD's fiber opening machines?

Different industries have different requirements for opening equipment, and INNOLD is chosen by customers in over 60 countries worldwide because of its "customization capabilities, understanding of processes, and stable quality." Our advantages include:

Manufactured to European standards, ensuring stable and durable operation.

Supports customized configurations for various industries (toys, home textiles, automotive, recycling, etc.).

High degree of automation, suitable for large-scale production.

Professional after-sales team providing video guidance and online technical support.

Whether you are a small factory just starting out or a large enterprise producing millions of pillows annually, we can provide you with the most suitable Fiber Opening Solution.

Want to learn about the fiber opening machine model that's right for you? Contact us for a free consultation!

If you are looking for a fiber opening machine suitable for your industry,

or are unsure which configuration best suits your production materials and capacity,

Please feel free to contact us anytime. INNOLD provides free consultations and customized solution designs.

We are happy to help you find the most suitable equipment combination to make your production more efficient and worry-free.

Post time:2025-12-13