Pillow Fiber Opener High Quality Home Textile Fiber Opener Fiber Opening Machine For Pillow Filling Machine

Pillow Fiber Opener High Quality Home Textile Fiber Opener Fiber Opening Machine For Pillow Filling Machine

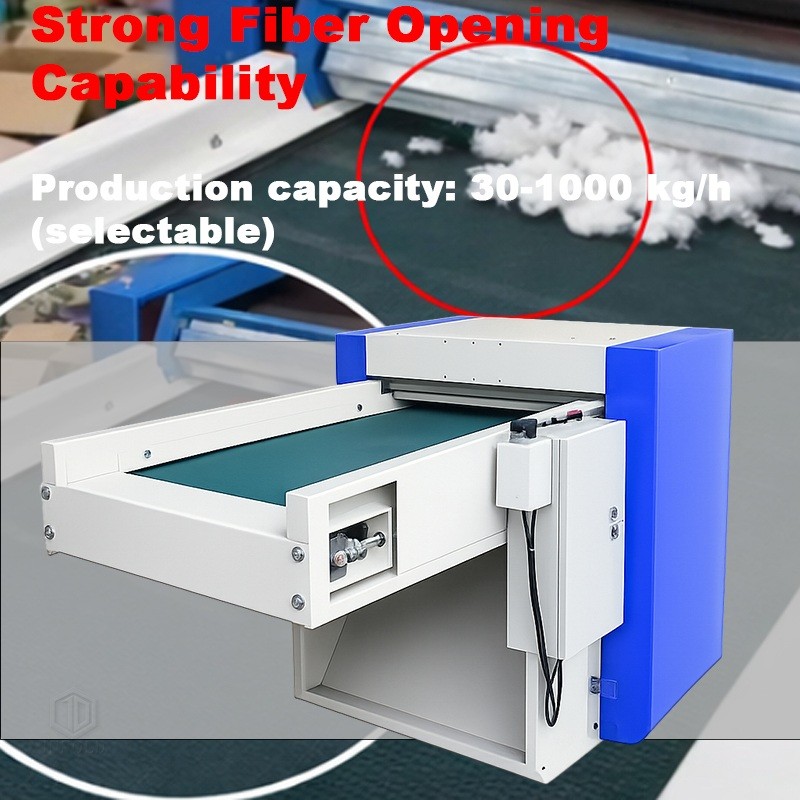

The Pillow Fiber Filling Line is a professional pre-processing machine designed to open, loosen and separate compressed fiber materials into a fluffy and uniform state.

It plays a critical role in Fiber Filling Production Lines by ensuring stable feeding, high fluffiness and smooth downstream operation.

Fiber Opening And Pillow Filling Machine is widely used in pillow filling, plush toy stuffing, cushion production, sofa filling and nonwoven fiber processing.

| Model | IN003F | IN004F | IN005F | IN006F |

| Capacity | 60-90kg/h | 120-150kg/h | 260-300kg/h | 300-500kg/h |

| Voltage | Customizable | |||

| Power | 3.25kw | 4.25kw | 5.75kw | 7.8kw |

| Size | 1800*650*850mm | 2200*800*920mm | 2200*1300*1080mm | 2200*1500*1080mm |

| Weight | 250kg | 350kg | 500kg | 700kg |

| Other Capacity can be Customized | ||||

It is the most advanced, the smallest size and the most powerful products athome and abroad.

It can open 15%-20% more per hour than similar products.

Fiber Opener For Pillow Filling is fully enclosed with neat beautiful appearance. Besides. it has itsown protection device.

This Machine is casy and safe to operate, lift and install.

This Machine uses puling force produced by thehobbing to open all kinds fibers, It loosen and open more than 99%, Besides, it has the same loosening effect on the woolen blanket and theleRover bits.

Fiber Opening Machine For Pillow Filling is used for evenly opening and fluffing two-dimensional/three-dimensional spiral cotton, PP cotton, doll cotton, and ordinary hollow fiber cotton. It requires only one pass for complete opening and is suitable for toy factories, sofa factories, bedding factories, and home textile and garment factories. It can also be used to open up old wool, wool sweaters, and old cotton quilts. Loading the cotton is easy, saving labor and improving efficiency.

Working Principle Home Textile Fiber Opener:

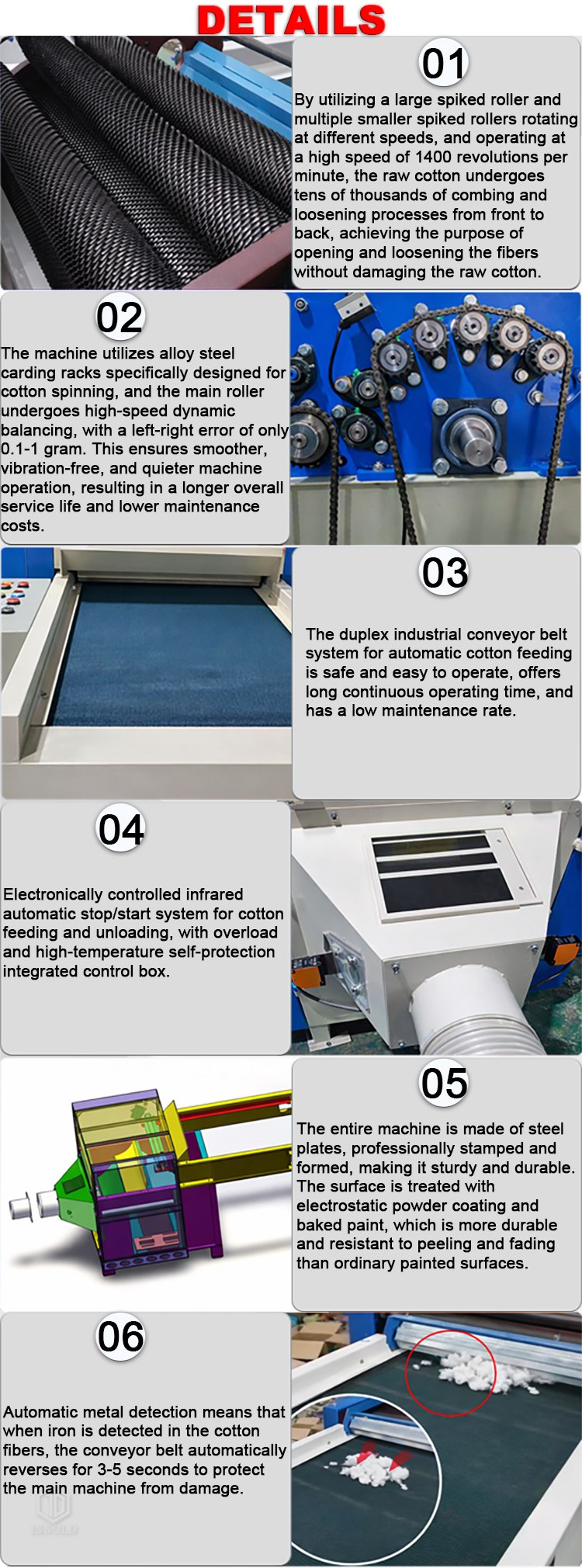

The fiber opening machine uses a high-speed opening roller with special steel spikes to tear and separate compact fiber blocks.

Working process:

Fiber material is fed into the machine manually or automatically

Opening roller disperses fiber clusters efficiently

Fiber is loosened into fluffy condition

Fiber is delivered continuously to the next machine by airflow or conveyor system

This process significantly improves fiber uniformity and feeding stability.

Applicable fiber materials Quilt Fiber Opening Machine:

Polyester staple fiber

Hollow conjugated fiber

PP cotton

Recycled fiber

Toy filling fiber

Pillow fiber

Sofa and cushion fiber

Down-like synthetic fiber

(Custom fiber types such as cotton, hemp or blended fiber can be supported upon request.)

Main features and advantages Stuffing Fiber Opening Machine:

1.High Opening Efficiency

Powerful opening roller ensures excellent fiber separation without damaging fiber structure.

2.Uniform Fiber Output

Stable and continuous fiber feeding improves consistency for downstream filling machines.

3.Adjustable Opening Intensity

Opening speed and feeding rate can be adjusted according to fiber type and density.

4.Strong Structure Design

Heavy-duty steel frame guarantees stable operation and long service life.

5.Easy Operation & Maintenance

Simple control system, low maintenance cost, suitable for long-time industrial operation.

6.Compatible with Production Lines

Can be connected with fiber feeding machines, weighing filling machines and automatic filling lines.

Application Fiber Opening And Filling Line:

Plush toy manufacturing

Pillow and cushion production

Home textile industry

Sofa and furniture filling

Mattress production

Fiber recycling plants

Nonwoven fiber processing