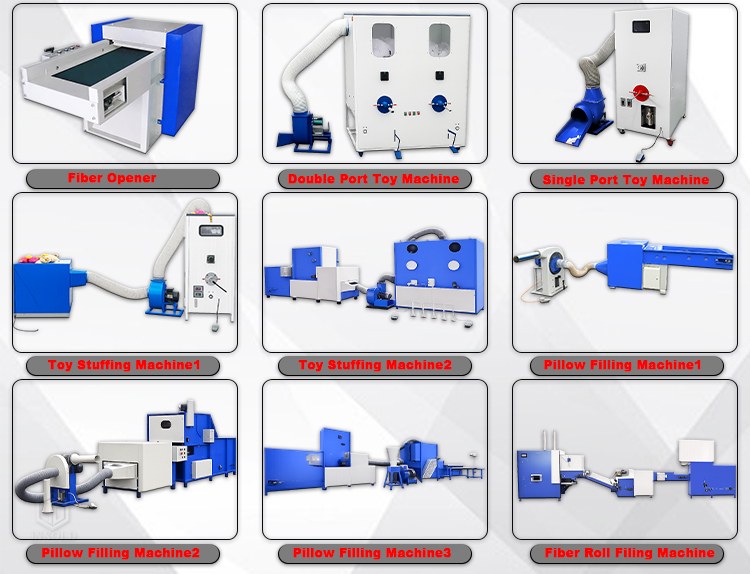

Fiber Toy Stuffing Machine Diy Stuffed Animal Stuffing Machine Long Service Fife Stuffing Teddy Bear Machine

Fiber Toy Stuffing Machine Diy Stuffed Animal Stuffing Machine Long Service Fife Stuffing Teddy Bear Machine

| Product Name | Diy Stuffed Animal Stuffing Machine | ||

| Model | ABB-1550(Single) | AB-005(Double) | AB-006(Double) |

| Capacity | 50-60kg/h | 80-100kg/h | 150-200kg/h |

| Air Pressure | 0.6-0.8Mpa | ||

| Voltage | Customizable | ||

| Power | 0.75kw | 1.5kw | 2.2kw |

| Size | 1200*800*1550mm | 1200*800*1550mm | 1400*900*1650mm |

| Weight | 250kg | 350kg | 500kg |

| Other Capacity and model can be Customizable | |||

Stuffing Teddy Bear Machine adopts the electronic pedal microswitch and the reliable and advanced control technology, which enables the machine to load and control the cotton and precisely controls the amount of cotton spraying.It adopts thickened gas tank to ensure that the machine has a strong enough working pressure.The machine adopts dismountable multiple cotton pipe to meet the needs of filling toys of different sizes. It has the advantages of high speed, fluffy effect, softness, elasticity and less cotton consumption. The gas consumption is reduced by 30% compared with the same kind of products. Besides, this machine saves power and reduces cost, and is suitable for filling toys, pillows, cushions, sofas, etc.

The Build Your Own Bear Stuffing Machine cotton after filling feels softer and the work efficiency is more than 15 times of manual cotton filling; This series is the first choice of many processing equipment manufacturer; The Machine can fill materials including: cloth, PP cotton, fiber, foam particles,sponge and avian hair.

Advantages of the Stuffing Machine For Stuffed Animals:

1. High-Efficiency Filling

The Doll Fiber Filling Machine is designed for continuous and stable operation, significantly increasing filling speed and production efficiency. It is an ideal choice for mass production of plush toys, stuffed dolls, cushions, and soft products.

2. Even and Fluffy Filling Effect

With an optimized airflow structure and precise fiber control, the machine ensures even distribution of fibers inside the doll, creating a full, soft, and natural filling effect, avoiding hard lumps or fiber clumping.

3. Clean and Dust-Proof Design

Equipped with an intelligent airflow system, it smoothly expels excess air during the filling process, effectively reducing fiber flyaway and maintaining a clean and safe working environment.

4. Easy Operation, Reduced Labor Costs

The simple control system allows one operator to easily complete the filling work. This greatly reduces labor intensity and helps factories reduce production costs while maintaining consistent quality.

5. Wide Range of Applications

Suitable for various materials such as polyester fiber, PP cotton, recycled fiber, and microfiber. The machine can be widely used in plush toys, dolls, pillows, cushions, sofa fillings, and decorative products.

6. Stable Structure and Durable

Manufactured with heavy-duty steel structure and high-quality electrical components, ensuring long service life, stable performance, and low maintenance costs.

7. Customizable Solutions

Filling capacity, workstations, and system configurations can be customized according to different production needs, helping customers build efficient and flexible filling production lines.