Plywood Hot Press Machine Hydraulic Cheap Wood Hot Press Machine For Sale

Plywood Hot Press Machine Hydraulic Cheap Wood Hot Press Machine For Sale

Plywood Hot Press Machine uses a hydraulic system to generate strong pressure, while a heating plate (hot press plate) provides a stable high temperature. This rapidly cures the glue in the wood or artificial board, firmly bonding the layers together and forming a smooth, structurally stable board.

| Product Name | Three-layer hot press | Four-layer hot press | Five-layer hot press |

| Nominal Total Pressure | 1600KN | 2000kn | 2000kn |

| Number of Hot Platens | 4 Pieces | 5 Pieces | 6 Pieces |

| Specifications of Hot Platens | 3200*1600*42mm | 2500*1300*42mm | 2600*1300*42mm |

| Unit Surface Pressure | 3.12kg/square centimeters | 6.5kg/square centimeters | 6.15kg/square centimeters |

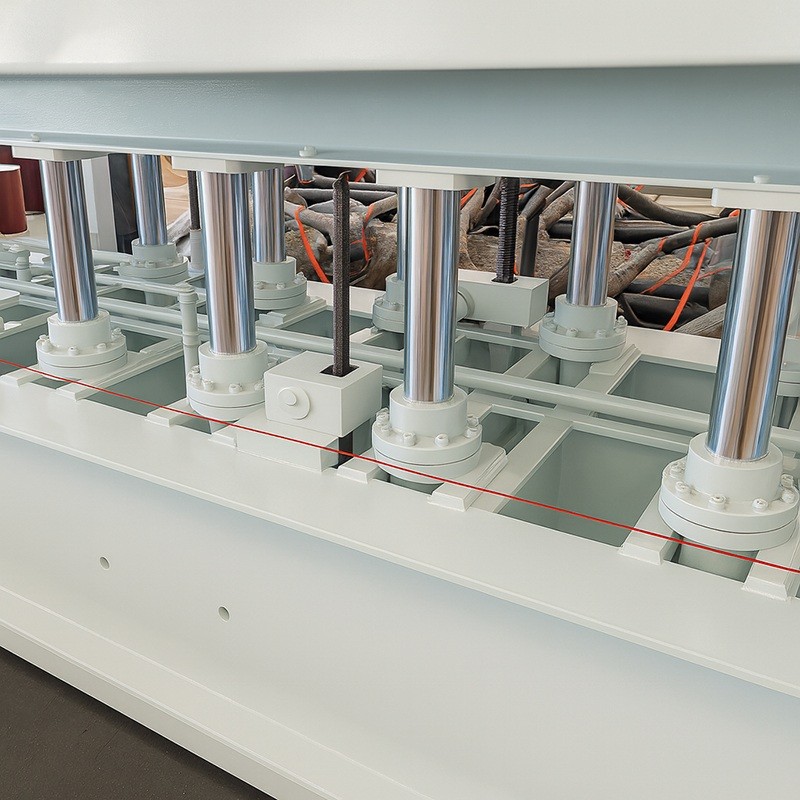

| Number and Diameter of Cylinders | 8 pieces/100mm | 10 pieces/100mm | 10 pieces/100mm |

| Closing Speed | 40mm/s | 40mm/s | 40mm/s |

| Heating Method and Medium | Electric heating medium circulation | Electric heating medium circulation | Electric heating medium circulation |

| Plate Opening Method | Electric | Electric | Electric |

| Gap Between Hot Platens | 100mm | 100mm | 100mm |

| Rated Hydraulic Pressure | 25mpa | 25mpa | 25mpa |

| Cylinder Stroke | 300mm | 400mm | 500mm |

| Installed Power | Hydraulic 7kW, Heating 36kW/Conductive 4kW | Hydraulic 7kW, Heating 36kW/Conductive 1.5kW | Hydraulic 7kW, Heating 36kW/Conductive 4kW |

| Maximum Operating Temperature | 180°C | 180°C | 180°C |

A: The basic process includes Plywood Hot Press Machine:

Loading: The glued veneer or board is stacked together.

Heating and Pressing: The machine heats to a set temperature (usually 120–180°C), and a hydraulic cylinder provides the required pressure.

Pressure-Dwelling and Curing: The high temperature and high pressure are maintained for a period of time to fully cure the glue.

Pressure-Relief and Discharging: The pressure is released and the pressed board is removed.

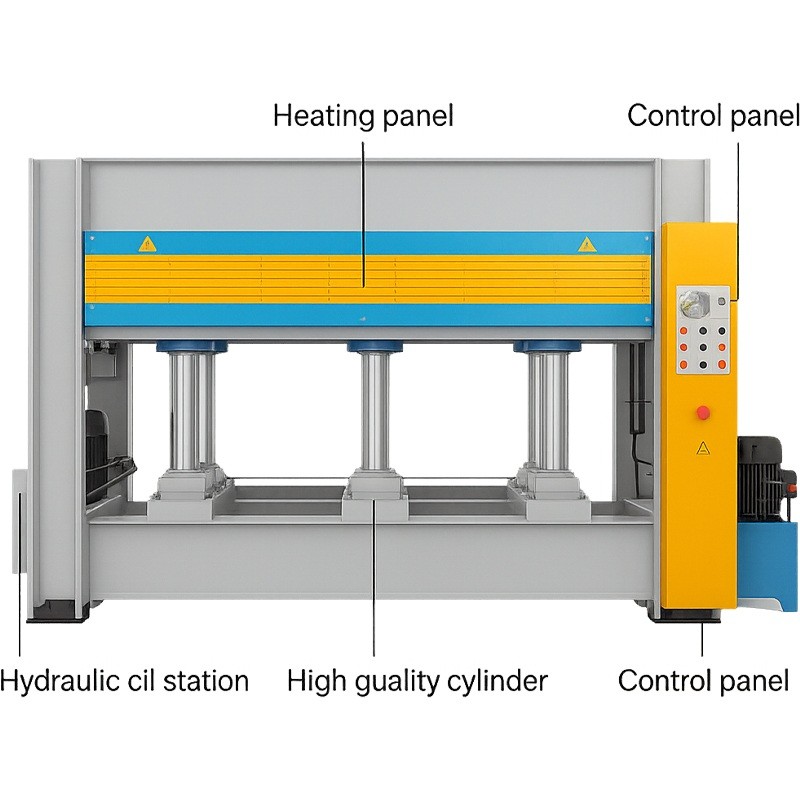

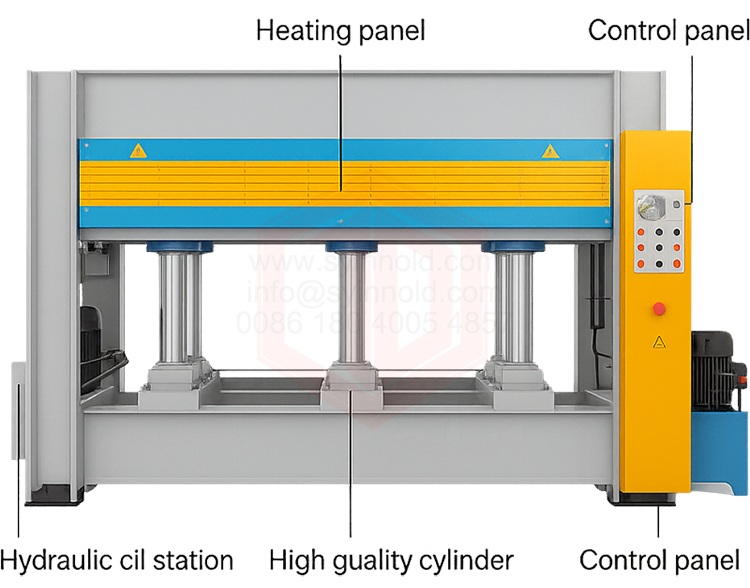

B: Main Components Plywood Hot Press Machine

Heating Plate: Conducts heat and ensures uniform temperature.

Hydraulic Cylinder: Provides high pressure to achieve the desired pressing effect.

Control Panel: Sets parameters such as temperature, pressure, and time.

Hydraulic Oil Station: Drives the hydraulic system. Heating System: Common heating methods include electric heating, steam heating, and thermal oil heating.

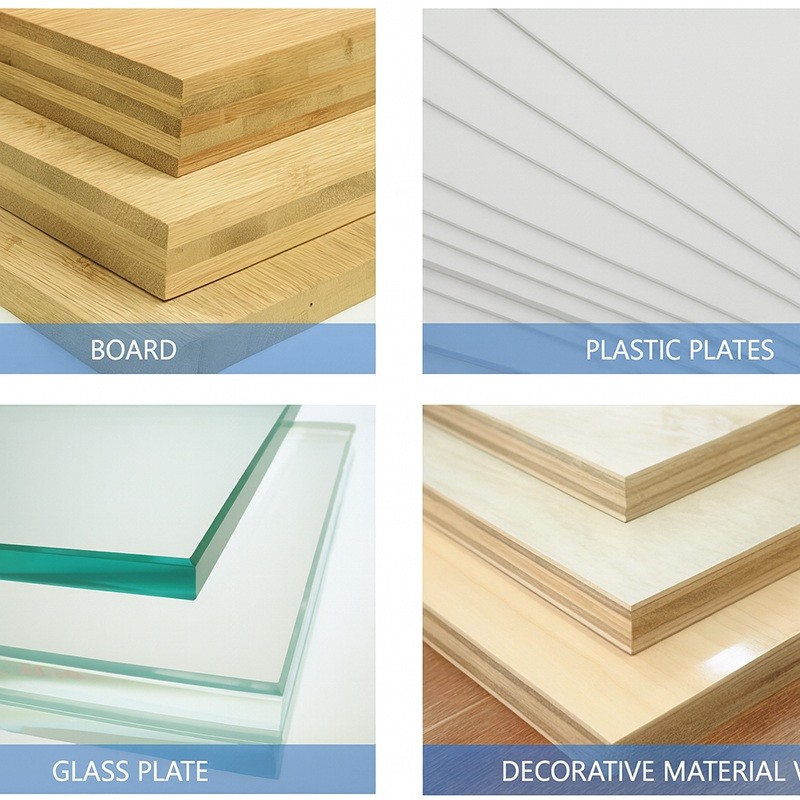

C: Common Applications

Hot pressing of wooden door veneers (composite doors, fire-rated doors);

Laminating of wood-based panels and plywood;

Veneering of furniture and decorative panels;

Laminating of flooring surfaces;

Hot pressing of aluminum honeycomb panels,

electric heating panels,

PVC composite panels, and polyurethane foam panels

D: Equipment Features

Stable pressure and high forming precision;

Uniform heating and strong bonding;

Adjustable temperature and pressure;

High degree of automation,

labor-saving;

Suitable for hot pressing of a variety of materials