What Fibers Can Be Processed By The Fiber Opening Machine?

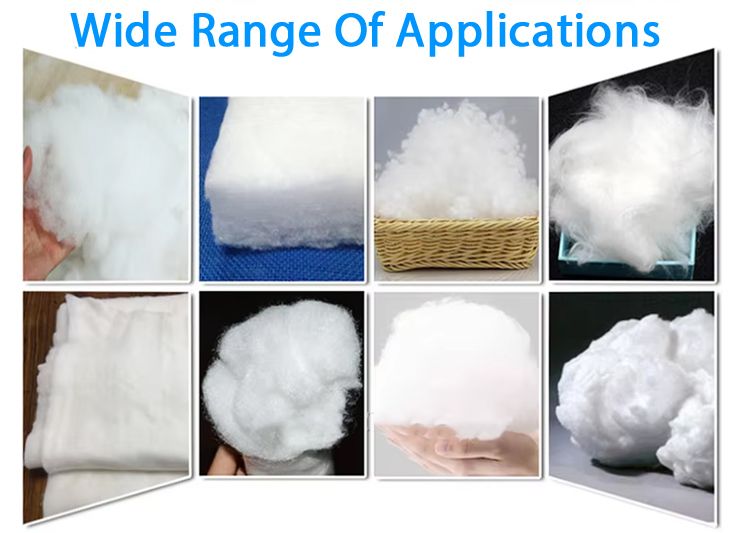

When purchasing Ball Fiber Opener, companies that produce pillows, bolsters, and stuffed dolls often face a question: Which fibers can be processed by the Cotton Opener? The original design of the opener is to finely comb and open the loose fiber raw materials to make the filling more fluffy and uniform. The fiber opener is suitable for various types of filling cotton materials. It can evenly open common fibers such as PP cotton, spiral cotton, doll cotton, hollow cotton, down cotton, etc. Through the opening process, the fiber raw materials become more fluffy and more uniform, and the filling feels softer and fuller, and it is not easy to clump.

Hollow polyester Adjustable Fiber Opener

Hollow polyester fiber is a commonly used filling material for pillows and plush toys. This type of fiber has good elasticity and air permeability due to its hollow structure. After being opened by the fiber opener, the hollow polyester fiber will greatly expand, making the filling softer and fuller, while the fiber distribution will be more even and less likely to clump. Industry data also pointed out that the surface of siliconized polyester fiber is smooth and soft, and the degree of opening itself is already very high. After opening, it can almost achieve the ideal fluffy effect. In short, opening the siliconized hollow polyester fiber can significantly improve the filling quality and make the pillow core and doll filling more comfortable.

Recycled Automatic Bale Opener Machine

Fiber openers are also widely used in the field of recycling and regeneration to process waste fiber raw materials. Whether it is waste pillow filling cotton, waste cloth scraps, or old clothes and old quilts after washing, the opener can process them. Regenerated fiber openers are mainly used to process waste cloth scraps, old cotton, clothes and other materials. After the opening process, the old fibers are fully disassembled and combed, and the fluffiness and elasticity are restored, and they can be used as secondary fillings. This not only realizes the recycling of resources, but also reduces the cost of raw materials. It should be noted that recycled fibers often contain impurities, and the corresponding cleaning equipment can further improve the opening effect.

Man-made fibers such as viscose and tencel Automatic Fiber Opener

Viscose fibers and tencel fibers are also types of fibers that can be processed by the opener. Viscose fibers are easy to entangle with each other when dry, and a large opening process is required to evenly disperse the fibers; while tencel fibers are smooth and soft, and relatively easy to open. Smooth tencel fibers require almost no additional strong opening to achieve good results, while viscose fibers require strong opening to be thoroughly dispersed. After opening, the fluffiness of these man-made fibers is significantly improved, and the texture and resilience of the fillings are improved. Therefore, whether it is the production of viscose pillow cores or Tencel filling products, the selection of appropriate opening equipment can ensure the opening effect.

Natural fibers such as cotton and wool Automatic Fiber Opening Machine

Compact Fiber Opening Machine can also be used to process natural fibers such as cotton and wool, especially when recycling waste quilts and sweaters. These natural fibers will also become fluffy and uniform after being processed by the opener. Therefore, for example, pure cotton and wool in waste sweaters can be processed and opened by the opener. After opening, these natural fiber fillings are softer and fuller, which improves the warmth and feel of the pillow or pillow, and also extends the service life of the product.

Fluffy and uniform: The fibers are fully combed after opening, the filling is softer and fuller, and the touch is significantly improved. The one-time opening rate can reach 99%-100%, leaving almost no fiber clumps.

Efficiency improvement: The Continuous Fiber Opening Machine has a high degree of automation and can continuously process a large amount of fiber raw materials, greatly improving production efficiency and reducing the time of manual tearing.

Cost saving: Automatic Waste Cotton Opening Machine reduces labor input and human errors, reduces unevenness and raw material waste. Used in conjunction with filling equipment, it can also simplify the process and improve the overall production line efficiency.

The Automatic Fiber Processing Line can effectively open a variety of filling materials (including hollow polyester, recycled fibers, artificial fibers and natural fibers). Manufacturers should choose the appropriate opener model according to the type of fiber they use and the output requirements. Finally, it is reminded that the corresponding opening scheme should be selected according to the characteristics of different fibers to maximize the efficiency of the equipment.

Post time:2025-05-06