What Materials Can The Sponge Crusher Process?

Automatic Spong Cutting Machine is a kind of equipment specially used to cut various sponges and foam plastic materials into small particles or fragments. It can not only efficiently process various polyurethane foams such as ordinary sponges, slow rebound sponges, memory sponges and latex sponges, but also crush plastic foam materials such as PVC, PE, EVA, and even various foam plastics such as EPS, EPE, EPP, XPS, PUR, etc., to meet various application needs such as furniture filling, toy filling and environmental recycling.

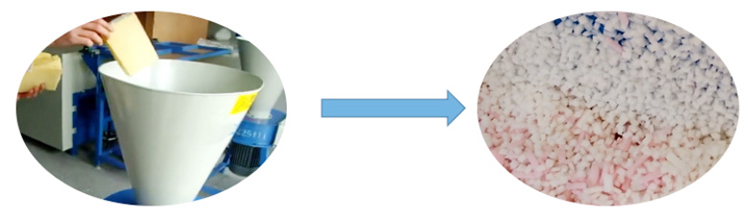

Foam Crusher Machine for Polyurethane sponge

Ordinary sponge, recycled sponge: suitable for the most common PU sponge scraps and waste on the market, the crushed particles can be used for recycled filling materials.

Slow rebound sponge (memory sponge): The machine's special cutter and speed design can easily tear the slow rebound sponge, achieving rapid cracking and efficient separation.

Latex sponge: In view of the high elasticity and adhesion characteristics of latex sponge, the crusher is equipped with a wear-resistant blade that can stably chop the latex sponge into particles.

Waste polyurethane foam: Supports secondary crushing of waste PU foam (density 15-80kg/m³), and selects different particle sizes for recycled products.

Foam Crushing Machine For Plastic foam

PVC, PE, EVA and other plastic foams: Using a sheet-type knife holder, it can simultaneously crush a variety of soft foams and plastic products such as PU, PE, PVC, EVA, etc.

EPS (polystyrene foam): A dedicated EPS foam crusher can cut expandable polystyrene into 3-60mm particles for granulation or recycling.

EPE (pearl cotton) & EPP (expanded polypropylene): Suitable for efficient crushing and recycling of waste EPE and EPP foam materials. The crushed particles can be used for recycling or filling.

XPS (extruded polystyrene) & PUR (polyurethane): It can also process hard insulation boards and polyurethane foams. The machine structure and cutters can adjust parameters for different densities.

Mixed foam plastics: The multi-stage crushing and screening system is compatible with a variety of foam mixtures to ensure uniform discharge.

Other compatible materials

Textile and cloth waste: Some sponge crushers are designed to take into account the crushing needs of soft materials (such as non-woven fabrics, knitted fabrics) and sponge products, and are suitable for the treatment of mixed sponge and cloth waste.

Through the above diverse material application range, the Pu Foam Shredding Machine can meet the needs of different production and recycling scenarios:

Furniture and toy filling - Use the crushed sponge particles for pillow cores, cushions, plush toys, etc. to ensure uniform filling and feel;

Environmental recycling and reuse - Efficiently crush waste foam, plastic foam, etc., and cooperate with granulation or hot pressing to achieve resource circulation;

Industrial application - Processing insulation materials, packaging foam, etc., preparing building insulation boards, lightweight concrete aggregates, etc.

When choosing a Foam Shredding Machine, please choose the most suitable model and configuration based on the main material type you process (such as PU sponge, EPS foam, EPE pearl cotton, etc.) and production capacity requirements, combined with the equipment's tool structure, speed adjustment and screen configuration, to achieve optimal production efficiency and material utilization.

Post time:2025-05-07