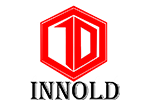

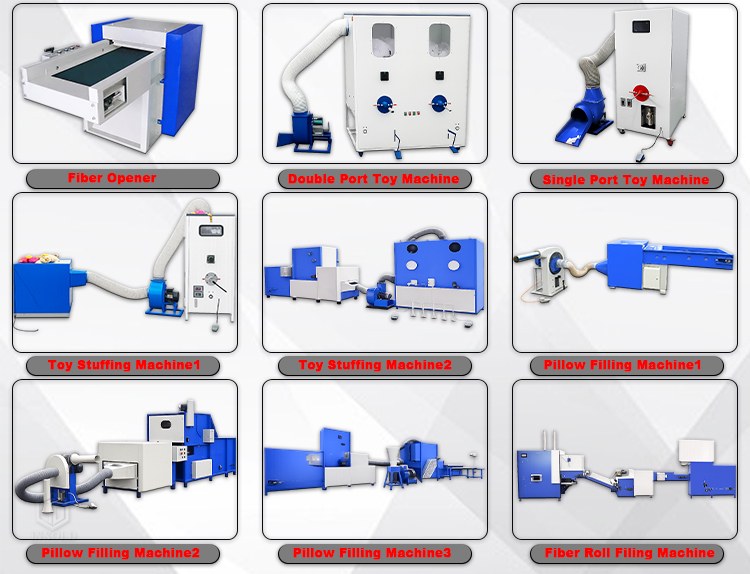

Filling Pillow Machine From China Polyester Fiber Opening Toy Stuffing Machines

Filling Pillow Machine From China Polyester Fiber Opening Toy Stuffing Machines

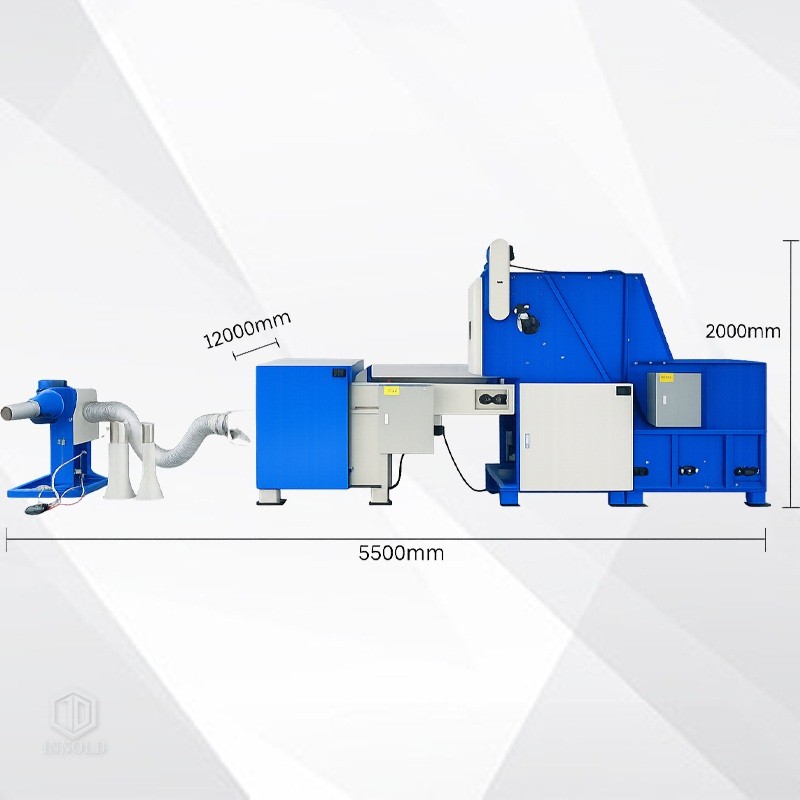

The Filling Pillow Machine is a complete set of equipment for automatic quantitative filling of pillow cores or pillows. By streamlining the processes of raw material conveying, opening, cotton blending, quantitative filling and subsequent clamping operation, it can achieve efficient, stable and controllable pillow core production. This production line not only greatly reduces the manual transfer and sorting links, but also ensures the consistency of filling amount and product quality. It is suitable for a variety of filling materials such as polyester fiber, microfiber, tufted fiber, natural wool, etc.

1.Fiber Feeder

| Model | IN005F | IN005F1 | IN005F2 |

| Capacity | 60-200kg/h | 60-300kg/h | 30-120kg/h |

| Air pressure | 0.6-0.8Mpa | ||

| Voltage | Customized | ||

| Power | 1.85kw | 2.95kw | 2.95kw |

| Size | 2000*1600*2100mm | 5800*1600*2100mm | 2000*1000*1700mm |

| Weight | 300kg | 450kg | 380kg |

| Other Production Quantities Can be Customized | |||

This automatic Cotton Feeding Machine is primarily used for the automatic feeding and pretreatment of fluffy materials such as polyester fibers, PP cotton, and hollow fibers, providing a stable and uniform supply of raw materials to downstream opening and filling machines.

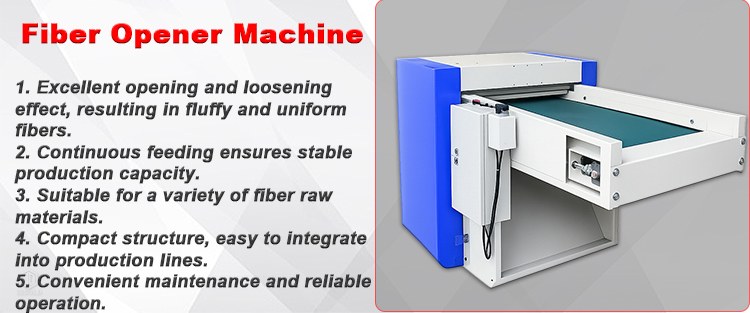

2.Fiber Opening Machine

| Model | IN003F | IN004F | IN005F | IN006F |

| Capacity | 60-90kg/h | 120-150kg/h | 260-300kg/h | 300-500kg/h |

| Voltage | Customizable | |||

| Power | 3.25kw | 4.25kw | 5.75kw | 7.8kw |

| Size | 1800*650*850mm | 2200*800*920mm | 2200*1300*1080mm | 2200*1500*1080mm |

| Weight | 250kg | 350kg | 500kg | 700kg |

| Other Output Can Be Customizable | ||||

It is the most advanced, the smallest size and the most powerful products athome and abroad.

It can open 15%-20% more per hour than similar products.

This is fully enclosed with neat beautiful appearance. Besides. it has itsown protection device.

This is casy and safe to operate, lift and install.

This Machine uses puling force produced by thehobbing to open all kinds fibers, It loosen and open more than 99%, Besides, it has the same loosening effect on the woolen blanket and theleRover bits.

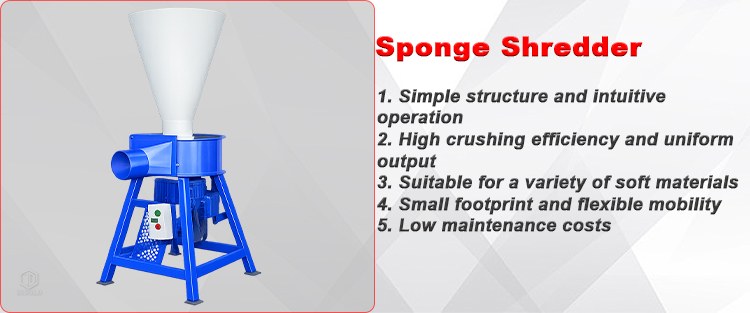

3.Sponge Shredder

| Model | AB200-4 | AB300-4 | AB400-4 |

| Capacity | 40-50kg/h | 70-80kg/h | 100-120kg/h |

| Size | 680*600*1200mm | 1020*800*1500mm | 1100*500*1400mm |

| Voltage | Customizable | ||

| Power | 4.0kw | 7.5kw | 11kw |

| Weight | 100kg | 180kg | 350kg |

| Other Capacity can be Customizable | |||

Sponge Crusher is a kind of equipment specially used to cut various sponges and foam plastic materials into small particles or fragments. It can not only efficiently process various polyurethane foams such as ordinary sponges, slow rebound sponges, memory sponges and latex sponges, but also crush plastic foam materials such as PVC, PE, EVA, and even various foam plastics such as EPS, EPE, EPP, XPS, PUR, etc., to meet various application needs such as furniture filling, toy filling and environmental recycling.

4.Fiber Blowing Machine

| Model | AB420-6 | AB430-6 |

| Size | 450*650*600mm | 450*650*600mm |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 70kg | 75kg |

The Cotton Suction Machine is a special conveying equipment that uses the airflow negative pressure principle to "suck" loose fiber cotton (such as polyester fiber cotton, down, PP cotton, pearl cotton, etc.) from the silo or bag and transport it to the next process (such as opener, Quantitative Filling Machine, filling machine). It is widely used in modern home textiles, toys, clothing and recycled fiber recycling production lines, which can effectively replace manual handling and improve the level of production automation.

5.Fiber Mixing Machine

| Model | AB1000-2 | AB1250-2 |

| Size | 1000*1300*1700mm | 1250*1550*1700mm |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 160kg | 180kg |

The Fiber Mix Machine is used in sofa factory, pillow factory and toy factory. It aims to mix all kinds of loosen short fiber or doll cotton with other filling materials (such as: broken sponge, wool, feather and so on)evenly.

It connects with the doll Cotton Filling Machine and can fill it in the designated cloth bag. Our company can provide the corresponding machinery and equipment according to the actual cotton scale requirements of customers.

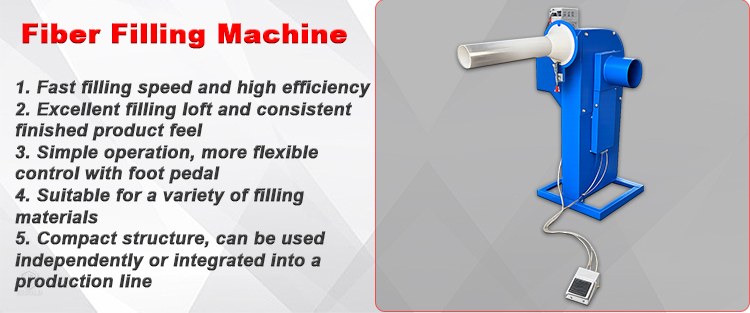

6.Fiber Filling Machine

| Model | AB-320-1 | AB-420-1 |

| Size | 650*1000*850mm | 650*1000*850mm |

| Voltage | Customizable | |

| Power | 1.5kw | 2.2kw |

| Weight | 110kg | 120kg |

This Air Cushion Filling Machine is designed for products which need fiber filling,such as a pillow, sofa and cushion.

Air Cushion Filling Machine uses larger caliber cotton pipe, which has high filling speed.The filled products will be fluffy, not rolled into granular.

The Air Cushion Filling Machine products will be soft and flexible products and a variety of fiber cotton is suitable for this machine.

Our Air Cushion Filling Machine is also equipped with an air return vent, which improves the bagging process and prevents fibers from being blown everywhere by the airflow.

7.Weighing Platform

The Weighing Platform is a device specially used for quantitative weighing of filling materials such as polyester fiber cotton, pearl cotton, feather velvet, etc. It is widely used in the automated production lines of soft products such as pillows, cushions, and dolls. Its core function is to accurately weigh the loose fibers according to the preset weight and convey them to the filling machine to ensure that the filling weight of each product is consistent, thereby improving production efficiency and product consistency.

Optional/Extended Configuration Filling Pillow Machine:

Automatic bagging and back-end stitching: Integrate automatic sewing machines or heat sealers to seal or sew the filled pillow core at the tail to form a complete product.

Fully automatic packaging machine: Connect the pillow packaging machine to pack the finished pillow (pillow film packaging), label, spray code or automatically pack the finished pillow.

Automatic loading and unloading: Equipped with Z-type elevators and finished product lifting chains to achieve unmanned transportation of raw materials and finished products.

Production level: According to customer needs, the optional production capacity ranges from dozens of pieces/minute to hundreds of pieces/minute, and supports modular upgrades (manual → semi-automatic → fully automatic).

Application scenarios Filling Pillow Machine:

Home textile industry: Production of various pillows such as household fiber pillows, buckwheat pillows, and pearl cotton pillows;

Pillows and home accessories: Inner core filling of various specifications and shapes such as pillows and cushions;

Toy filling: Some companies can also use it for fiber filling of dolls and plush toys after modification.