What equipment is needed for a complete Pillow Filling Machine line?

Many customers ask us when inquiring about Pillow Filling Equipment, "If I want to build a complete Pillow Production Line, what machines do I need?"

This is a very typical question. While pillow production seems simple, a complete Pillow Filling Line is essential for achieving high efficiency, automation, and product consistency. Today, from the perspective of a manufacturer, I'll guide you through the equipment included in a complete pillow filling line.

I. Fiber Opening Machine – Making Fibers Fluffier

The first step in the production line is the Fiber Opening Machine.

Raw synthetic fibers, pearl cotton, or seven-hole fibers are often in a clump or compressed state, requiring the opening machine to loosen them.

The function of the opening machine is:

To fully disperse and fluff the fibers

To improve the softness and elasticity of the pillow filling

To lay a good foundation for subsequent quantitative filling

INNOLD's opening machines use a double-roller or multi-roller structure, combined with an automatic dust removal system, making them both efficient and clean, ideal for large-scale continuous production.

II. Fiber Storage Box (Cotton Storage Warehouse) – Ensuring Stable Feed Supply

The opened fibers are fed into the fiber storage box. This step ensures even storage and a stable feed supply.

With the fiber storage box, the entire production line avoids inaccurate weighing due to sudden overfeeding or underfeeding, guaranteeing consistent filling weight for each pillow.

III. Fiber Filling Machine – The Core Component

This step is the core of the entire production line. The **fiber filling machine** is responsible for automatically filling the pillowcases with the opened fibers according to a set weight.

Its advantages include:

Automatic weighing, with an error controllable within ±1g

Allows setting different weight parameters to accommodate pillows of different sizes

Easy operation; one person can control multiple machines.

INNOLD's intelligent fiber filling machine supports multi-station operation, capable of filling two or four pillowcases simultaneously, significantly increasing production capacity.

IV. Sealing Machine – Neat Edge Sealing, Improved Efficiency

After filling, the pillows need to be quickly sealed by a sealing machine (sewing machine or overlock machine). This step is typically handled by an automated conveyor system, employing either traditional sewing or optional heat sealing or ultrasonic sealing methods to ensure the pillowcase is flat, aesthetically pleasing, and sturdy.

V. Shaping and Beating Machine (Optional)

Some high-end production lines also include a pillow shaping and beating machine.

Its function is to distribute the pillow filling more evenly and create a fuller shape within the pillowcase. Pillows treated with this beating process appear more three-dimensional and are more comfortable.

VI. Automatic Packaging Machine (Optional)

For export factories or e-commerce companies, the final step often involves an automatic packaging machine to achieve:

Pillow compression packaging, saving transportation space

Automatic sealing and packing, improving shipping efficiency

VII. Integrated Control Line Control System

A complete pillow filling line is typically controlled by a PLC intelligent system, achieving seamless integration of processes such as automatic feeding, filling, weighing, sealing, and packaging.

Operators only need to set parameters on a touchscreen for automatic operation, significantly reducing manual labor.

VIII. Summary: INNOLD Makes Pillow Filling Simpler

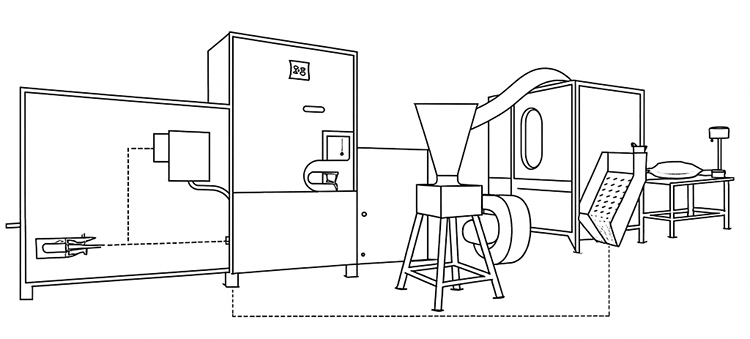

Therefore, a complete pillow filling line generally includes: Opening machine + Container storage box + Quantitative Filling Machine + Sealing machine (shaping and packaging machines can be added).

INNOLD has focused on fiber processing equipment for over ten years. All our equipment is manufactured according to European standards, ensuring stable operation, high precision, and long lifespan.

We not only provide single machines but also customize complete production line solutions based on your factory space, product type, and production capacity requirements.

If you are planning to build or upgrade your pillow production line,or are unsure which configuration is best for your product,

Please feel free to contact us. We can provide you with free consultation and solution design services.

We are happy to help you build an efficient, intelligent, and energy-saving Pillow Filling Production Line.

Post time:2025-11-01