What products can a fabric shredder process?

Many customers, when visiting our factory for the first time, always point to a machine and ask, "What is this fabric shredder mainly used for? What materials can it shred?"

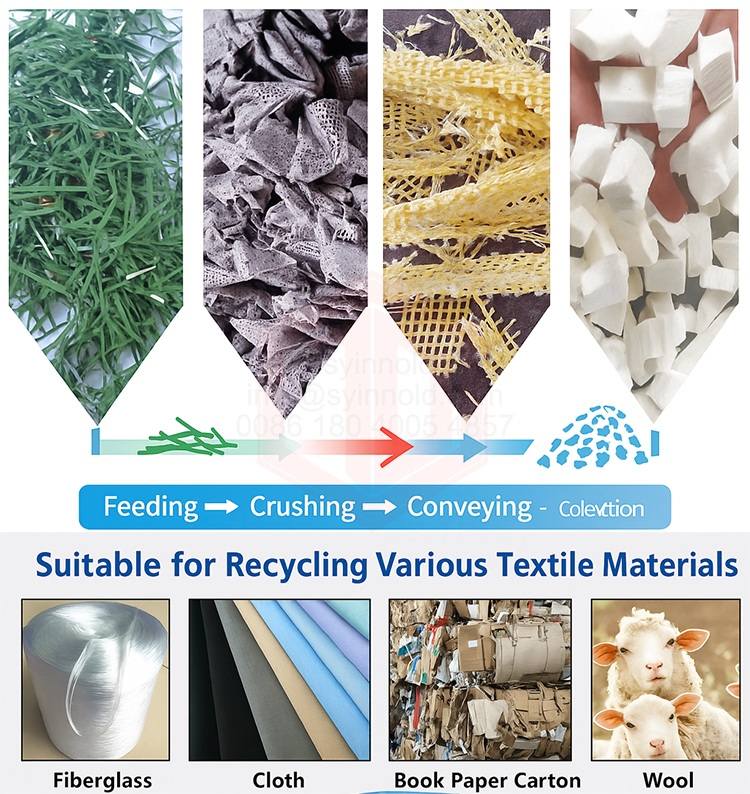

In fact, this machine has a much wider range of uses than most people imagine; it's not just about shredding old clothes and waste fabric. As a manufacturer, we encounter different customer needs every day, from textile mills to sofa factories, from clothing recycling companies to automotive interior factories—fabric shredders are practically everywhere. Today, based on our experience, I'll explain in detail what products it can process.

I. Textile Fabrics and Scrap Materials

This is the most common use of a fabric shredder.

Materials such as cotton, synthetic fibers, nylon, denim, and canvas generate a large amount of scrap material during the production process in textile mills or garment factories.

Fabric shredders can uniformly shred these fabric scraps, facilitating subsequent reuse, such as:

Making recycled fibers

As filling materials (pillows, toys, sofa cushions)

For the production of recycled cotton and non-woven fabrics.

This not only reduces waste but also gives waste fabric a new lease on life.

II. Old Clothes and Recycled Textiles

Many customers now come from the recycling industry, using fabric shredders to process recycled old clothes, sheets, curtains, etc.

The shredded fabric can be used for:

Producing recycled cotton yarn

Making thermal insulation and sound-absorbing cotton

As filling materials in the automotive and home furnishing industries.

This type of processing is not only environmentally friendly but also aligns with the current trend of circular economy development.

III. Leather, PU, and Artificial Leather Materials

Besides fabric, fabric shredders can also process some flexible materials, such as:

Leather scraps

Artificial leather, PU leather, and synthetic leather.

These materials, after being processed by specialized rollers, can be shredded into small pieces for the production of insoles, leather granules, and recycled composite materials.

IV. Non-woven Fabrics and Industrial Fabrics

Materials such as non-woven fabrics, needle-punched fabrics, geotextiles, and dustproof fabrics have strong fibers and are not easily torn.

These materials can be easily shredded using a specially configured high-speed blade and pressure-stabilized feeding system. Suitable for:

Medical non-woven fabric recycling

Filter cloth and wiping cloth reuse

Industrial fabric scrap recycling

V. Materials for Sofa, Mattress, and Toy Industries

These customers primarily use fabric shredders to process:

Sofa fabrics and mattress fabrics

Toy fabrics and plush fabric scraps

These scraps can be directly used as recycled filling materials, significantly saving raw material costs.

VI. Customized Special-Purpose Shredders

Some customers have special requirements, such as wanting smaller fabric particle sizes, higher output, or dust removal functionality.

We can customize these, for example:

Configuring an automatic dust removal system

Adding a conveyor belt and storage hopper

Adjusting the blade roller structure according to material hardness

INNOLD's fabric shredders support various customization options to meet the production needs of different factories.

VII. Summary

In short, fabric shredders can process the following products:

Various textile fabrics (cotton, linen, synthetic fibers, nylon)

Waste clothing and scraps

Non-woven fabrics, needle-punched fabrics, industrial fabrics

Leather, artificial leather, PU leather

Fabrics used in sofas, mattresses, and toys

It is a versatile, environmentally friendly, and energy-saving machine that truly saves costs for businesses.

As a professional fabric shredder manufacturer, INNOLD's equipment is manufactured strictly according to European standards, ensuring stable performance and high durability. Customized designs can be provided according to customer needs.

If you would like to know which model is more suitable for your raw materials,or if you want to establish a complete fabric recycling production line,

Please feel free to contact us. We can provide you with free technical consultation and equipment solutions.

Post time:2025-11-08